Kaimusailing

s/v Kaimu Wharram Catamaran

| Vessel Name: | Kaimu |

| Vessel Make/Model: | Wharram Custom |

| Hailing Port: | Norwalk, CT |

| Crew: | Andy and the Kaimu Crew |

| About: | Sailors in the Baltimore, Annapolis, DC area. |

17 April 2024 | St Marys, GA

Dinghy Skeg

I was suffering with what seemed like a cold and also had allergy symptoms. I awoke and felt fine. The green pollen that was coating everything was gone. Maybe it will return.

07 April 2024 | St. Marys, GA

Clammy Hands

Items came in from TEMU, the Chinese cut rate retailer. One was a nice little drone that cost about twelve and a half dollars. It looked like an easy thing to play with while I coughed and sneezed. I was fighting a summer cold, even though it is not summer elsewhere, it seems like it here. A nice [...]

02 April 2024 | St. Marys, GA

Sun Doggie

After laminating the cedar strips onto the gunwales of the dinghy I found the screws I used wouldn’t come out. The epoxy had seized them. The screw heads were stripped so I cut a straight slot in the heads with the cut off wheel. The cedar smoked when the screw heads got red hot. I could remove [...]

21 March 2024 | St. Marys, GA

Just Add Water

The rainy weekend started off with overcast and fog but no rain. It looked like I might be able to get something done on the D4 dinghy. I wanted to change the bow seat which is really the bow deck. The sailing option uses the deck to hold the freestanding mast. I didn’t like how the deck looked, [...]

01 March 2024 | St. Marys, GA

D4 Dinghy Alternative Seats

The rain event was more wind than rain, strong winds with gusts up to 44 mph. We drove into town to see what the harbor was like. There was a small sailboat that had dragged anchor and was sitting close to shore. The tide was out. We left and played with Bleu at Notter’s Pond.

23 February 2024 | St. Marys, GA

D4 Inside Seams

Day two of the dinghy build started out with me finishing wiring the hull bottoms together on the centerline of the bottom panels. This was much easier than the wiring of the chine edges of the bottom panels and the side panels.

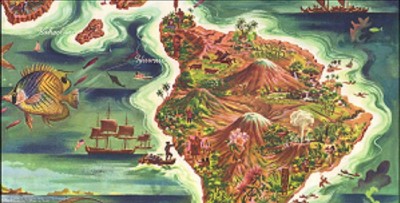

A Brief Hawaiian Interlude

The mast was repaired, but needed to be checked up above, and that would need to wait for cooler weather. I decided to secure the boat for a couple of weeks and pay a visit to my folks and hope the weather would back off. Also we were getting into hurricane season and July into August could be the last chance to make a trip without a hurricane rearing up while we were away.

I was happy with the way the mast turned out, but I was unsure about the condition of the wood up above. It looked like a job for the electric bos'uns chair. Also the anchor light at the top of the mast, the steaming light about 1/3 the way down, and the spreader light all needed to be repaired. Probably just corroded contacts. LED bulbs would drop the amp hour requirement and last a lot longer as well. This work will be done later, after the return from Hawaii.

The delay of working on the forward storage spaces was about a week. The delay caused by the mast repair was another week. The heat is adding delays just as bad as the cold of winter. Even the eager sailors haven't been down at the docks. Now we would add 2 weeks of delay by taking a vacation from retirement.

One reason to take a vacation now was my parents' 70th anniversary. My dad was trying to rehab from a stroke and my mom was home alone with only occasional visits from my siblings. My brothers and sister on the Big Island bore the brunt of the responsibility of caring for the aged parents. The rest of us could only visit for a week or two and help out a little.

It turned out to be another family food fest. My mom makes great apple pie, but needs help, mainly with preparing the apples. We made 3 pies at first and those were gone in a couple of days. We had two more pie making sessions, and each time the pies were gobbled up.

Time seemed to fly by quickly and I found myself sadly climbing aboard a jetplane back to the mainland. I was eager to get back to work on the boat and also maybe take some day trips locally on Chesapeake Bay

The weather was cooler, but humid, after I returned. For some reason, it was hard to get motivated to work. There were more repairs to the deck table, which seemed to be fragile. There were thunderstorms, hail, and flooding.

The job that was lurking ahead was the holding tank. I like to use the apprehension of a nasty project as motivation to take care of a bunch of lesser projects. The holding tank was the nastiest project I could think of. All the work I was doing was in lieu of working on the loo, that is, I was putting off working on the holding tank and working on anything else. Now it became clear to me while I was ruminating in Hawaii, I was avoiding the inevitable. It must be dealt with.

There was evidence of a holding tank leak and I cleaned that mess up. This was a couple of years ago. I kept a space heater going in the holding tank compartment all winter to prevent the contents from freezing and cracking open the tank, which was what I had thought had happened to make the big mess that I had to clean up. When we brought another yacht into the marina to pump out the holding tank, I remarked to the dockman that I too had to get my holding tank pumped out and I hadn't had it done for a few years. He said it was too late and at this time it would probably be a concrete accretion of sediment in the holding tank that would never be able to be pumped out. "You'd have to chip it out", he said. And so I worried about it for weeks and went ahead and worked on anything else, but did not go near the holding tank.

These things become larger than they really are. A completely new holding tank was only 161 dollars, with free delivery. Of course the prospect of removing the old one and working with that plumbing, was unthinkable.

I finally went aft to the port aft compartment with a premeditated procedure to work on that holding tank. I had a long paint mixing attachment for the drill and I reasoned, it would either mix up what was in the holding tank, or fail, bumping against the concrete accretions at the bottom. I needn't mention the aspect of the mixture that might result when I did this. Success might be as unpalatable as failure. Was there any way to stave off any flesh eating bacteria, or brain eating amoeba?

The result was no big slurry of waste products or the attending stench. It was very liquid, which seemed to indicate they were right, it had all solidified on the bottom. Careful measurements showed that the bottom was where it should be, there was no layer of accreted concrete. We were "Good to go" to have the holding tank pumped out.

I began also replacing the rigging lashings, which replaced turnbuckles. Turnbuckles are metal, work great for tensioning a stay, but metal can fatigue and fail, so we went with dynema lashings. The lashings can deteriorate from UV radiation, so after a few years they should be replaced. It's hard to get tension with a lashing, but tension is difficult at all on a catamaran. Tension on the mast stays tends to push the mast, which is situated over the center of the cross deck, down, and the result is the cross deck bending. Modern catamaran rigs get away from the old fashioned high tension monohull rigs by using a large mainsail, which needs no stay tensioning, and a small blade jib, which can be tensioned with running backstays while underway as needed. The downwind sail is a spinnaker or gennaker that is flown from a bowsprit. I began to think of my genoa as a downwind sail, so it didn't need high tension. When I tensioned both forestays, they were similar, which was what I was after, until now. Now I wanted to make the inner forestay taught and let the genoa stay be somewhat tight. I released the running backstays which were tensioning the forestays, and then tensioned the genoa's headstay. Then I removed the lashing from the inner forestay, which is also called the stays'lstay, and put new dynema in there and tensioned it up.

Some of the skippers dragged me into a steak fry and gave me a rough time about why I hadn't taken the boat out, and I related all the work we had done and how our goals were delayed all summer. Certainly we would be going down the inlet to get the holding tank pumped out, and then why wouldn't we go out for a shakedown sail?