Kaimusailing

s/v Kaimu Wharram Catamaran

| Vessel Name: | Kaimu |

| Vessel Make/Model: | Wharram Custom |

| Hailing Port: | Norwalk, CT |

| Crew: | Andy and the Kaimu Crew |

| About: | Sailors in the Baltimore, Annapolis, DC area. |

23 April 2024 | St Marys, GA

D4 Launchie

The laptop pooped the bed, so I have to scurry around with alternatives. Not as bad as typing on the phone.

17 April 2024 | St Marys, GA

Dinghy Skeg

I was suffering with what seemed like a cold and also had allergy symptoms. I awoke and felt fine. The green pollen that was coating everything was gone. Maybe it will return.

07 April 2024 | St. Marys, GA

Clammy Hands

Items came in from TEMU, the Chinese cut rate retailer. One was a nice little drone that cost about twelve and a half dollars. It looked like an easy thing to play with while I coughed and sneezed. I was fighting a summer cold, even though it is not summer elsewhere, it seems like it here. A nice [...]

02 April 2024 | St. Marys, GA

Sun Doggie

After laminating the cedar strips onto the gunwales of the dinghy I found the screws I used wouldn’t come out. The epoxy had seized them. The screw heads were stripped so I cut a straight slot in the heads with the cut off wheel. The cedar smoked when the screw heads got red hot. I could remove [...]

21 March 2024 | St. Marys, GA

Just Add Water

The rainy weekend started off with overcast and fog but no rain. It looked like I might be able to get something done on the D4 dinghy. I wanted to change the bow seat which is really the bow deck. The sailing option uses the deck to hold the freestanding mast. I didn’t like how the deck looked, [...]

01 March 2024 | St. Marys, GA

D4 Dinghy Alternative Seats

The rain event was more wind than rain, strong winds with gusts up to 44 mph. We drove into town to see what the harbor was like. There was a small sailboat that had dragged anchor and was sitting close to shore. The tide was out. We left and played with Bleu at Notter’s Pond.

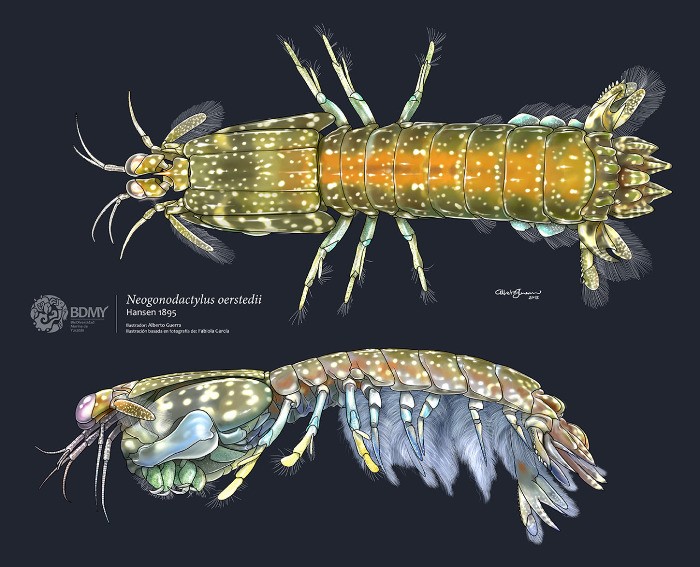

Rocky Shrimp

.

The chainsaw bit on the angle grinder was used to dig out more of the slot for the port skeg. I wanted to get a 2 to 3 inch deep slot, but the bit will only cut to about 1 inch of depth. It really hogs out the material and I was covered in wood chips and saw dust. A car pulled into our area and the young Russian ran over to it. Some friends? It turned out it was a couple he had met at Jekyll’s Island. They had made the trip to the boatyard to visit him.

.

At some point I was introduced and a bit later I hinted we should go to dinner to continue our sailing stories. We went to the local Thai restaurant and I told the story of hitting the jetty. They said they had heard about it and there was a picture online of Kaimu on the beach. They found it and showed it to me on their cell phone. I could see myself onboard, it must have been the first visit on the Sunday after the crash.

.

The two ladies who sailed up to the boatyard to get their cutlass bearing replaced were referred by this couple and that is why the ladies were asking for the Russian, since they were also going to Cuba. Small sailing world.

.

The weather took a turn to wetter and colder. It was time to shop again so I reserved an economy car to run my errands. When I got to the car rental place they again asked if I would take a larger vehicle for the same price. I agreed. It was a cargo van, huge.

.

I took advantage of having the large vehicle and went to the lumber store and bought two dozen 2X6‘s and a dozen 2X4‘s. The 2X6‘s were construction grade lumber picked out of the pile with no large knots. The 2X4‘s were rough sawn cedar, not as nice grade, but I bought more than necessary to enable using just the good parts and cutting out any bad knotty parts.

.

The plan was to use the lumber for beam replacement. The cedar is a light wood that glues well and is resistant to bugs and rot. The pine is stronger wood. The pine will be used as top and bottom of the beam, like an I-beam, with the cedar the vertical part of the I. The resultant beam will be strong and lighter than a beam made with rectangular section of stacked planks.

.

The work in the galley area included hunting down a foul smell coming from somewhere. I had cleaned the starboard hull of any sludge, the sludge being made up of beach sand, mud, sea water soaked macaroni, and an added slurry of bolognese sauce along with some ole mole chili. The smell was strongest over by the batteries, which are stored under the outboard dinette seat. That area was recleaned. The batteries were then hoisted onto the edge of the dinette seat and the shelf they had been sitting on was lifted. Below it was a void, the lowest part of the space below the dinette seat. Sand fleas began hopping out. At the very bottom was a very foul thick dark smelly sludge.

.

It took several buckets of pine scented cleaner to dissolve and remove the mess. After it was cleaned, I continued down into the bilge. Then I did the other side of the dinette, which wasn’t bad at all. The galley now had a nice piney smell and the batteries were returned to their place.

.

I had too many dishes on board and the extras had been stowed in the spaces below the dinette sole, so they got the brunt of the sand and muck that inundated the galley. I had two loads of dishes to wash and had to schlep them across the boatyard to the communal kitchen.

.

I had bought a 7 inch flap disk intending to put it on the 4 1/2 inch angle grinder, safety guard removed. One of the contractors in the boatyard said it wouldn’t fit, “Arbors are different”. Not so, it fit. It’s kind of like a hot-rod angle grinder. I used it to fair the external surface of the patch at the galley planking. It was a big new disk and ate up whatever it came in contact with. It also imparted a significant amount of gyroscopic effect to the little grinder, so I had to compensate when I moved it around. It wanted to twist and grind off my wrist.

.

The patch had self tapping screws in it to hold it together when it was glued up, so they had to be removed. Now that they were embedded in epoxy, they didn’t want to budge. Actually most of them did come out without much trouble using the 1/2 inch variable speed drill with a cross head screw bit. One didn’t and the head of the screw was damaged. Nothing worked to remove it. I tried vice grips on the protruding point of the screw and tried to clean out any epoxy in its head, but the head was so damaged the screwdrivers couldn’t get a grip. What finally worked was a small channel lock plier gripping the protruding point and then gripping the grips of the small channel lock with a huge pair of channel locks. It wasn’t easy getting all these parts to work together, but once they did, the screw began to come loose and then it was routine to remove it.

.

Raw epoxy was brushed onto the patch and squirted into the screw holes with one of the syringes from Walmart. I’ve found they have marinade injection syringes on sale in the outdoor living department for less than a dollar. Too bad I bought out the other type for almost 4 dollars each. I was able to use the original syringe over and over by breaking the epoxy loose after it hardened. Then I forgot once and the whole syringe was full of epoxy and that was the end of it.

.

After the raw epoxy, batches were made with colloidal silica and that was injected into the screw holes and filled into the cracks with a scraper. It will probably take another session of filling with an even thicker batch after this one is set up and ground fair with that big flap disk.

.

I bought some rock shrimp from one of the boatyard workers and had no place to keep it frozen, then I remembered my old freezer from the boat was now in the hands of gruff boatyard manager who got it working. I asked him if I could put it there and he said yes. When I opened the freezer an awful smell came out. The Blue Ice blocks in the freezer’s tray weren’t frozen. The power light was lit on the front of the freezer, but the operational light was not. I put the bag of shrimp in the manager’s other freezer and told him something was wrong with the little freezer.

.

Later there was an awful stench in the boatyard. It was a quantity of shrimp that had gone bad in the little freezer. The manager said, “Easy come, easy go”, and I said “It’s mostly easy go”.

.