Kaimusailing

s/v Kaimu Wharram Catamaran

| Vessel Name: | Kaimu |

| Vessel Make/Model: | Wharram Custom |

| Hailing Port: | Norwalk, CT |

| Crew: | Andy and the Kaimu Crew |

| About: | Sailors in the Baltimore, Annapolis, DC area. |

23 April 2024 | St Marys, GA

D4 Launchie

The laptop pooped the bed, so I have to scurry around with alternatives. Not as bad as typing on the phone.

17 April 2024 | St Marys, GA

Dinghy Skeg

I was suffering with what seemed like a cold and also had allergy symptoms. I awoke and felt fine. The green pollen that was coating everything was gone. Maybe it will return.

07 April 2024 | St. Marys, GA

Clammy Hands

Items came in from TEMU, the Chinese cut rate retailer. One was a nice little drone that cost about twelve and a half dollars. It looked like an easy thing to play with while I coughed and sneezed. I was fighting a summer cold, even though it is not summer elsewhere, it seems like it here. A nice [...]

02 April 2024 | St. Marys, GA

Sun Doggie

After laminating the cedar strips onto the gunwales of the dinghy I found the screws I used wouldn’t come out. The epoxy had seized them. The screw heads were stripped so I cut a straight slot in the heads with the cut off wheel. The cedar smoked when the screw heads got red hot. I could remove [...]

21 March 2024 | St. Marys, GA

Just Add Water

The rainy weekend started off with overcast and fog but no rain. It looked like I might be able to get something done on the D4 dinghy. I wanted to change the bow seat which is really the bow deck. The sailing option uses the deck to hold the freestanding mast. I didn’t like how the deck looked, [...]

01 March 2024 | St. Marys, GA

D4 Dinghy Alternative Seats

The rain event was more wind than rain, strong winds with gusts up to 44 mph. We drove into town to see what the harbor was like. There was a small sailboat that had dragged anchor and was sitting close to shore. The tide was out. We left and played with Bleu at Notter’s Pond.

Beanball Bullseye

.

My ideas about getting back to work were now questionable. It looks like we will get a few merely hot days in between the familiar heat waves, so work will be intermittent. I was getting too optimistic.

.

When I look at last year's blog entries, which I do whenever I want to see how things played out last time, I could see that I was still up in Maryland and still a week away from my voyage down here in the little C&C 24, Trillium. That voyage ended up here near the end of September, and then hurricane Matthew struck the first week of October. This year we are still a month ahead of that schedule, so anything that I can accomplish now is a step ahead.

.

For some reason I remembered to check on Jack van Ommen's blog, www.cometosea.us/. I had followed it religiously when he was circumnavigating in his 30 foot plywood sloop, "Fleetwood". He then wrecked his boat near Ibizia in the Med. I suppose following Capn "Radio" Bill's voyage across the Atlantic and into the Med made me think of Jack. How was he doing? I knew he was able to get another identical plywood sloop which became the new Fleetwood. I was surprised to find he ran aground leaving the Chesapeake just a short time ago and his boat sank, and now he was trying to rebuild it. He is about 80 years of age and just had back surgery. He is planning to do the work himself. I wrote him to commiserate .

.

In the morning I could work, but the heat would begin as the sun rose overhead. I moved what I could into the shade. The outrigger canoe's crossbeams had been trimmed to fit the beam mounts and then edges were rounded off with the trim router. I sanded with 150 on the palm sander and gave a primer coat of epoxy. This is a thin coat which fills the pores in the wood so that the thicker following coats can build up a thick layer to keep moisture out of the wood.

.

I had been told that the poplar hardwood that I was using was prone to rot, and the crossbeams, which are sandwiches of poplar/cedar/poplar, were unfinished and stored out of doors for the past few months. It is obvious that the wood has taken on a dark color which usually indicates fungi are finding a home there. Once that happens, the wood is doomed to eventually be ruined by the fungus. It's an organism that has evolved to create its own ideal environment, it makes the wood porous and heavy with moisture. The fungus tries to travel through the wood and it travels along the wood grain quite easily, so a board that has rot on a small spot on one end might have the fungus already through it end to end, just not as advanced.

.

I sanded and epoxied the wood anyway. I can always make new crossbeams when these begin to fail. I will probably be itching to build a new design by then.

.

The daggerboard/rudder blade was sanded and epoxied too. Then it received a coating of epoxy thickened with 50/50 silica/microspheres. This was a very thin coating to fill any cloth weave still present.

.

Because I will refer to these posts later, maybe next year, I want to chronicle the hurricane news. It is important to see, year to year, when these storms arrive and what we thought about them before they arrived.

.

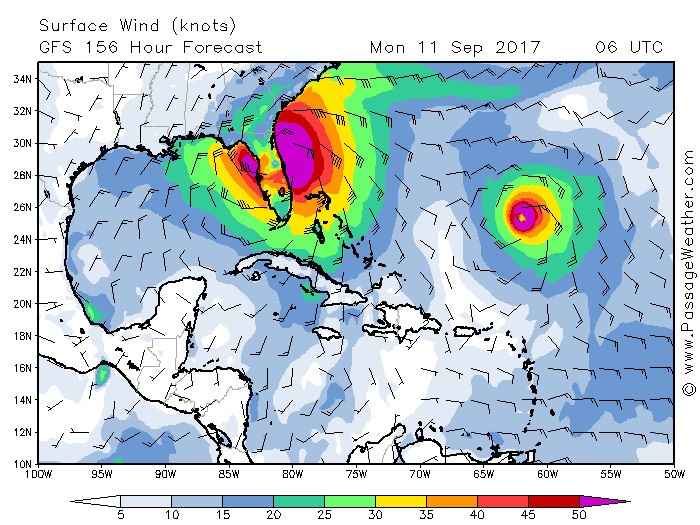

We have a hurricane that has been downgraded to a post tropical depression, Harvey, and it has poured a huge amount of rainwater on Galveston, Houston, and everything else on the way up to Nashville, Tennessee. And now we have another major hurricane, Irma, which has everyone abuzz about where it is going, north out to sea or south into the Caribbean Islands, the Bahamas, maybe even into St. Marys, Georgia. My guess right now is that it will impact the Bahamas and the coast of Florida and really hit the Carolinas.

.

I ended up only epoxying one side of the rudder/daggerboard, letting it lie flat so the epoxy could ooze into a smooth layer. The crossbeams were done with a pime coat of epoxy, then two normal thick coats. They will be painted. I mounted them back on the main hull and began to make the mast steps and mast partners. A typical mast partner on a small open sailboat would be a plank between the gunnels with a hole in it for the mast. On the proa we are making the partners out of fiberglass, glassing the mast in place with some plastic to separate things after the epoxy sets up.

.

I had a general idea of how the partners would be, fiberglass wrapped around the mast and crossbeam, but I didn't know how to build it. I had never built anything like that before. I looked through my fiberglass stores. I had cloth, matt, and two types of roving, the heaviest of the glass. One type was triaxial, which is two layers of flat rovings basted together with a third layer of stitching. This type of roving does not have a weave pattern, it laminates flat. The second kind is woven roving which has a basketweave pattern and needs matt laminated between the roving layers to fill the gaps. Some times roving is sold with matt already attached to the roving.

.

My preference was to unweave the woven roving and use the glass fibers to make a a bundle of glass yarns that I could soak with epoxy and then wrap around the mast and crossbeam. This required tedious unlaying of the woven rovings and organizing them in two piles, the longer lengthwise yarns in one pile, and the shorter crosswise yarns is a second pile. I decided to use only the long yarns and counted them. I would use 26 yarns in each lamination. The mast would be clamped to the crossbeam and the wae below it. Later I would install a mast step of poplar wood.

.

The mast was prepared by wrapping enough plastic cut from a dropcloth around the mast at the crossbeam level to make the diameter equal to the diameter of the foot of the mast. This is around 2.1 inches. Then another wrap was made at the wae level. A final plastic wrapped the lower 3 feet or so of the mast, so no epoxy could bond to it.

.

The hull was leveled and the mast was temporarily bungied into position and the crossbeam and wae were marked. Thin stainless wire (seizing wire) was used to wire the mast in place. Then a 60 ml batch of epoxy was mixed to soak the batch of rovings in. The rovings were then wrapped around the mast and crossbeam and small plastic squares about the size of postcards were clamped onto the wet glass on either side of the mast. The same was done for the wae.

.

The final step in the day's work was to flip the daggerboard/rudder over and paint it with the thickened epoxy. The next day I did the other mast partner, and was greeted by an ominous forecast for the hurricane Irma, it was projected to pass right through us in a week's time. The image is of passageweather's wind prediction for Florida, on 9/11.