Kaimusailing

s/v Kaimu Wharram Catamaran

| Vessel Name: | Kaimu |

| Vessel Make/Model: | Wharram Custom |

| Hailing Port: | Norwalk, CT |

| Crew: | Andy and the Kaimu Crew |

| About: | Sailors in the Baltimore, Annapolis, DC area. |

23 April 2024 | St Marys, GA

D4 Launchie

The laptop pooped the bed, so I have to scurry around with alternatives. Not as bad as typing on the phone.

17 April 2024 | St Marys, GA

Dinghy Skeg

I was suffering with what seemed like a cold and also had allergy symptoms. I awoke and felt fine. The green pollen that was coating everything was gone. Maybe it will return.

07 April 2024 | St. Marys, GA

Clammy Hands

Items came in from TEMU, the Chinese cut rate retailer. One was a nice little drone that cost about twelve and a half dollars. It looked like an easy thing to play with while I coughed and sneezed. I was fighting a summer cold, even though it is not summer elsewhere, it seems like it here. A nice [...]

02 April 2024 | St. Marys, GA

Sun Doggie

After laminating the cedar strips onto the gunwales of the dinghy I found the screws I used wouldn’t come out. The epoxy had seized them. The screw heads were stripped so I cut a straight slot in the heads with the cut off wheel. The cedar smoked when the screw heads got red hot. I could remove [...]

21 March 2024 | St. Marys, GA

Just Add Water

The rainy weekend started off with overcast and fog but no rain. It looked like I might be able to get something done on the D4 dinghy. I wanted to change the bow seat which is really the bow deck. The sailing option uses the deck to hold the freestanding mast. I didn’t like how the deck looked, [...]

01 March 2024 | St. Marys, GA

D4 Dinghy Alternative Seats

The rain event was more wind than rain, strong winds with gusts up to 44 mph. We drove into town to see what the harbor was like. There was a small sailboat that had dragged anchor and was sitting close to shore. The tide was out. We left and played with Bleu at Notter’s Pond.

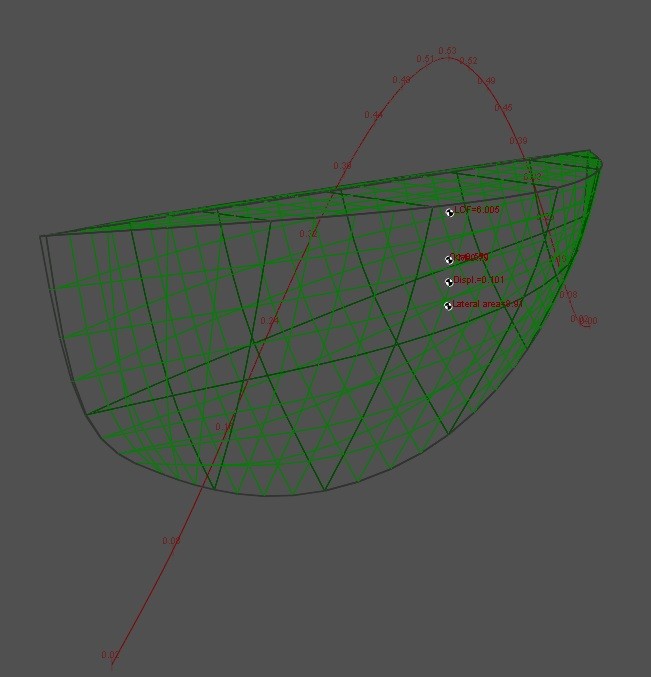

More Proa Design

.

The result of trial and error positioning of the scale model hull panels resulted in an incredibly dense cut layout with almost no waste. The hull sides and bottom have a seam amidships and another seam at 5 feet from each end. This works out well with the ends of the hull decked over from the bow to a bulkhead at 5 feet from the bow, then an undecked midships section that is a total of 8 feet long consisting of two 4 foot long panels and a seam amidships. All the hull panels including the decks and bulkheads can be cut from four sheets of ply.

.

Reviewing the proa hull construction written up in the blog in autumn of 2014 reminded me of the difficulties of building the crossbeam connections, largely as a result of using lashings to tie the crossbeams to the hulls. Simple glass/epoxy brackets and bolts will cut down on both construction time and hull assembly time at the beach. The outrigger end of the beam connections failed, so these too will be changed. The goal will be attachment to the gunwales of the ama (outrigger float), which will be an adaptation of the same 12 foot long tortured ply ama used back then. This time the ama planking will be made from 3 mm doorskin ply.

.

This design is not very original, sharpie bottomed proas were designed by Commodore Ralph Munroe way back in the 1890‘s, and Gary Dierking’s Wa’apa design has been around a while and built all over the world. John Harris of CLCboats.com has a 20 foot sharpie design, “Mbuli”, as well as an 18 foot sharpie monohull sailboat. A link on the tackingoutrigger.com website leads to a bunch of designs by O. Gulbrandsen who made them for the United Nations fisheries and they include a number of sharpies as well as skiff hulls.

.

The sharpie construction method is dirt simple, make the hull sides, lay them together and attach the ends with wire ties, spread them apart and glue in the bulkheads, then plank the bottom.

.

The 12 foot ama design in delftship was modified so that its deck would match the angle of the crossbeam, which will attach directly to the ama’s gunwales. Delftship doesn’t allow asymmetry, so a proa hull with more curvature on one side of the hull than the other can’t be drawn. The program mirrors the second hullside. Thus, if we want to have the inboard gunwale raised a bit (1 1/2 inches), we have to redraw the design with the higher gunwale and take offsets for the inboard hullside off the modified drawing. One of the problems with the ama of the last couple of prototypes was having the crossbeams spaced 8 feet apart and parallel, so that they crossed the ama only about 2 feet from each end of the ama. The new design is aiming for crossbeams 6 feet apart. This was chosen because one sailing rig we want to try is the freestanding schooner rig with two equal masts. We’d like to step the masts using the crossbeams as mast partners.

.

The delftship design program runs on the windows machine and won’t run on this machine, which is navigatrix operating system (linux). An earlier version of delftship, called freeship, can run on linux using the WINE windows application adapter. Unfortunately, designs saved from the latest versions of delftship cannot be opened in freeship. This means we can’t write the blog here and upload it with any delftship images without saving them to a thumbdrive and bringing them across that way, or uploading them from the windows machine.

.

Recreating a design in freeship or delftship isn’t a matter of starting from scratch and building the wireframe of the design by entering coordinates one by one, and what if you don’t have the coordinates of a design, although most lines drawings have a table of offsets to work from. In delftship and freeship a background image can be loaded, so you can load an image of a hull and build a wireframe based on that. Designs from other programs can be imported using the import function from most of the design software offered by the Carlson website. Carlson sells computer controlled cutting machines.

.

The image is of the ama design wireframe.