SV Panta Rhei Retirement Trip

| Vessel Name: | Panta Rhei |

| Vessel Make/Model: | Able Apogee 50 |

| Hailing Port: | Seattle |

| Crew: | Larry and Karen |

| Social: |

18 September 2017 | Seattle

We are back in Seattle

It feels like home. Of course we are not in Silshole. Maybe we will be, someday, but there is a list and we are on it. In the meantime we are at Bainbridge Island Marina.

23 August 2017 | Prince Rupert

The dinghy holds air again

It wasn't very nice of the bear to tear the fabric across a seam. We were worried that we couldn't patch it but tried anyway. The glue had a job to do and it did it!

15 August 2017 | Anan Bear Observatory

A Grizzly Bear damaged our dinghy

We were visiting the Anan Bear Observatory south of Wrangell. It is one of the best places to visit in all of SE Alaska BECAUSE it has bears. But (as we learned) there is a dark side to this bear concentration. And of course, there is a story to tell.

19 July 2017 | Petersburg, AK

Moving On

"No matter where you go, there you are" (unknown reference). By now we have been there and done that. Most recently that included Cannery Cove on Admiralty Island. The photo shows the quiet grandeur of the setting with Ron and Suzie's boat SV Tango in the foreground. It has been like that for the last [...]

17 June 2017 | Hoonah, AK

We are in Hoonah, SE Alaska now

We got something resembling a high pressure ridge so we moved expeditously across the Gulf of Alaska. The crossing took three days and weather stayed as forecast. That was a very good thing. The weather changes in the far north far more rapidly and dramatically than we ever experienced in the more southern [...]

03 June 2017 | Seward AK

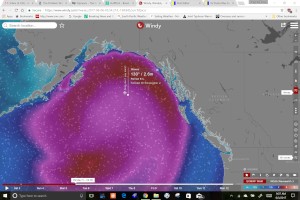

Crossing the Gulf of Alaska

We are still in Seward, AK. Now that spring has come, why not start south?

Sail panels are being cut

This will all take a couple weeks and then we get to go for a test sail. The excitement is building.