Sequitur

Michael & Edi have headed out on a slow, thorough exploration of the globe.

| Vessel Name: | Sequitur and Zonder Zorg |

| Vessel Make/Model: | 2007 Hunter 49 and 1908 Wildschut Skûtsje |

| Hailing Port: | Vancouver, Canada |

| Crew: | Michael Walsh & Edi Gelin |

| About: | For our current location click, on Map & Tracking, then on the Google Earth logo. |

| Extra: | Follow us on Twitter: Follow @YachtSequitur |

| Social: |

13 January 2014

Another New Book Released

I am delighted to announce that my new book: Carefree on the European Canals is now in print and is available on Amazon.com, Amazon.ca [...]

26 April 2013

New Book Released

The proof copy of my new book arrived by courier today. I have approved it and it is now listed on Amazon for pre-order, with a publication date of 30 April. It is a rather large book at 680 pages in an 8.5 by 11 inch format with 315,000 words illustrated by over 2400 colour photos, charts and maps. [...]

24 April 2013

One Year Out of Brazil

One year ago today we sailed Sequitur out of Brazil after enduring more than six weeks in the least-friendly country that we had experienced during our three-year voyage. In the early evening of 24 April 2012 we crossed the line on the chart dividing Brazil from French Guyana and breathed a huge sigh [...]

27 October 2012 | Harlingen, Friesland

Planing a Metamorphosis

We have added a new post to the Zonder Zorg blog at: Planing a Metamorphosis.

29 September 2012 | Sneek, Netherlands

Onward to Friesland

We have arrived in Friesland and have added a new post to the skûtsje's blog at: Onward to Friesland

19 September 2012 | Hoorn, Netherlands

North From Aalsmeer

We have moved northward from Aalsmeer and I have added two new posts: Heading North From Aalsmeer and North From Amsterdam

13 September 2012 | Aalsmeer, Netherlands

Taking Possession

We are back in the Netherlands, and I have added some new posts to the ZonderZorg blog at: Taking Possession and Settling-In and Making Plans

20 August 2012 | Sequitur: St Augustine, USA - Michael & Edi: Vancouver, Canada - Nieuwe Zorg: Aalsmeer, Netherlands

Added a New Website

We have added a new website: Skûtsje ZonderZorg. Zonder zorg in Dutch means without worry. Our intention with the site is to provide a place to share some of the history, geography and culture of the skûtsje as we discover it. We will also use this place to document [...]

11 August 2012 | Sequitur: St Augustine, USA - Michael & Edi: Vancouver, Canada - Nieuwe Zorg: Aalsmeer, Netherlands

Still More Skûtsje History

We continued to attempt to track-down Douwe Albert Visser, who was the owner of Nieuwe Zorg in 1941 when she was re-registered. One of the problems we repeatedly encountered in our online searches was the effect of currently having Albert Visser and two Douwe Vissers as very competitive skûtsje racers, [...]

10 August 2012 | Sequitur: St Augustine, USA - Michael & Edi: Vancouver, Canada - Nieuwe Zorg: Aalsmeer, Netherlands

Some More Skûtsje History

While I was researching the history of Nieuwe Zorg, I finally found her first registration details obscured by an apparent typographical error in a transcribed online spreadsheet. She was listed as having been built in 1901 instead of 1908. I emailed the webmaster of the [...]

Putting the Pieces Together in La Punta

I quickly dressed and welcomed Eugenio plus Luis and his lady friend, Milagro onboard. We discussed the Sea Rider dinghy, and we were told it was built in Korea by a company from the Netherlands. It is made from a composite polyurethane fabric named Akron, which is a relatively new European material with an ultraviolet and abrasion resistance between that of Hypalon and PVC. We talked technical details for a while, and then Luis and I went for a spin around the mooring field.

The dinghy he had brought to Sequitur was a 3.8 metre folding aluminium-floored model with an inflatable keel, and it was fitted with a Tohatsu 18-hp two-stroke engine. With the two of us onboard, it very quickly got up on plane and was very stable running at 15 to 18 knots. Back onboard, we talked some more and shared email addresses so that we could continue the discussion.

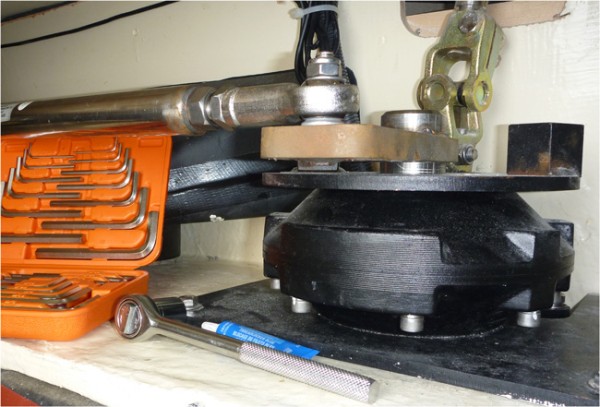

After Luis and party had left, I took my newly acquired heavy-duty 6mm hex wrench into the starboard transom locker and dismantled the end of the autopilot drive motor. I then replaced the end-piece, with its gears and damaged splines, with the spare end piece from Lewmar. I was working on the drive motor in the transom locker, rather than out in a more spacious place, so that I didn't have to undo all of the electrical connections on it. My next hope was that the somewhat flattened and rounded ends of the male splines would fit into the replacement female splines. To my relief, a bit of delicate alignment and a few heavy thumps with a fist sent the splines home. In theory, we now have our electrical autopilot working again. Confirmation will need to await a sea trial.

While I was repairing the autopilot, Edi had set-up our sewing machine in the cockpit, and was designing and sewing together a cover for our Hydrovane.

There is no doubt that the new blue cordura cover with its elastic draw-string is much nicer than was the former cover of plastic shopping bags and sticky tape.

On Monday morning Luis sent me an email with lots of additional technical information and some links to sites with more. We emailed back-and-forth a couple of times, adding greatly to my confidence both in his product and in him, and I learned everything I needed to know to make a well-informed purchase decision.

Luis is also the distributor for Tohatsu outboards, which is the brand that my research in Vancouver over the summer had pointed to as my first choice engine. They are the first builder of small gasoline engines in Japan as well as the first Japanese builders of outboards motors. Their new production facility has the capacity for 200,000 units per year, and they currently manufacture motors under the Tohatsu brand, as well as for Mercury, Nissan and others.

On Monday evening I emailed Luis, requesting a quote on a 3.6-metre dinghy and an 18-hp Tohatsu 2-stroke motor. He emailed me a formal quote, and with his reply he told me that he is buying a new 4.0 metre RIB and a 30hp engine, and that he was going to be putting into storage his current 18hp engine. He added, "... there is the possibility to sell my current in use motor, next week will perform its first 300 hour general maintenance to have it in form for this summer". I told him we were interested in the used motor, and asked him for a price. He asked when we could come with him to see the dinghies, and I said whenever it was convenient with him.

For dinner on Monday evening we enjoyed tarragon chicken with a butter sautee of mini portobellos, shallots and garlic, accompanied by mashed potatoes, fine green beans almandine and sliced Roma tomatoes. The 2009 Las Moras Reserve Chardonnay complimented very nicely.

On Tuesday morning Luis called us on VHF and said he was in La Punta and could take me to see the dinghies. I called a launch and went ashore to meet him, and we drove through the extremely heavy traffic past the port and airport to a residential area. He introduced me to Percy Estrada Rojas, his technical expert who, according to the certificates on the wall, has been for over fifteen years a well-trained repair and maintenance technician for Zodiac inflatables and liferafts.

Luis and Percy showed me an inflated and assembled 3.6-metre model, and I was pleased to see the capacity plate on the transom indicated that it was CE certified and conformed to the ISO9001 standards. It is constructed with Akron PE, a composite polyurethane fabric certified to have high resistance to abrasion, pollution and UV. The fabric was developed in Germany for use in professional and rescue craft, and is being used by the US Coast Guard and the Royal Navy, among others. It was designed as a better alternative to costly Hypalon fabrics.

The boat looked very-well built and solid. I was told that the fabric is 1.2mm thick, rather than the industry standard of 1.0mm or less for this size boat. At 3.6 metres, the new dinghy is half-a-metre longer overall than our former Walker Bay 310, and I needed to confirm that it would easily fit onto our davits, on which the falls are 185cm apart. I measured the new dinghy's distance from its transom to its forward internal eye-pads as 200cm, and assessed that this small difference would present no problem. Its beam of 165cm is identical to that of the Walker Bay, and its weight of 68.5 kilograms is only 7.5 kilos heavier. The maximum load is 689 kilos compared to 620 kilos for the Walker Bay.

The Sea Rider 3.6 comes with two carrying bags for the rolled boat and the aluminium floor panels, a wooden bow seat with side hooks, an emergency patch kit, two aluminium oars, a bow bag, a fitted tube cover, a Scoprega dual high and low-pressure foot pump, a Ceredi big-dial pressure gauge and air valve adapter, a can of 303 aerospace protector spray for the tubes and a complete installation course, including assembly and inflation procedures and overall care. For US$2,000 (which this week is CA$2,000), I thought it was a bargain.

I told Luis I would take the pale grey model with the blue trim, and I asked him to have the two forward eye-pad attachments reinforced so that we can use them as hoisting points. I also asked him to include a spare drain plug and a spare oarlock assembly.

On Tuesday afternoon Edi baked. She prepared a couple of loaves of potato bread, using the extra mashed potatoes I had made on Monday evening. While the loaves rose, she started on three different batches of biscotti: a slivered almond, an apricot and almond and a hazelnut and almond.

Baking is always a bit of a trick with a small gas oven in a boat's galley, but the three loaves rose and baked very well, and she found them easy to slice for their second baking.

By early evening we had six dozen biscotti. Edi then turned to the potato bread loaves.

The dough had risen wonderfully in the stable confines of the microwave oven. While she was back in Vancouver for the birth of her granddaughter last month, Edi had experimented with bread recipes, and this potato bread one was her favourite.

Finding good bread here in Peru, similar to our experience in Mexico; is very difficult. It is mostly too sweet or too tough. We had a baguette last week that nearly ripped our teeth out as we tried to bite-off, then tear-off a piece to eat. Edi's loaves had no chance to rest before we had sliced-off slabs to sample. Wonderful! Tender! Delicious!

On Wednesday morning, as the launch approached to take me ashore on a diesel run, I saw Steve Wagner in its bow. He handed me a rolled-up bundle, and I put it in the cockpit and boarded the launch. Steve had delivered the front centre panel of our dodger, in which he had replaced the window, after the tripulantes had been too aggressive in their cleaning efforts, and had fogged it into opacity.

Steve is widely reputed as the only sail-maker on the Pacific coast of South America, and couple of weeks previously we had walked with him from his sail loft to his tiny marine shop in the Mercado, and looked at his selection of plastic sheeting. He had a small piece of material identical to that which needed replacing. We now can see forward again from our cockpit.

On Wednesday afternoon, Edi and I took a bus to San Miguel and got off at Wong. The previous week we had taken advantage of a wine sale, offering 40% discount on many labels, and we had put a good dent into replenishing Sequitur's cellar. We had returned to continue the process. We picked-up an additional sixteen bottles, including half-a-dozen Frexinet Cordon Negro Cava at S/32.13, about $11.50 per bottle.

While we were there we also bought a 2.5 kilogram bonita tuna, and watched as the fishmonger cleaned it and cut it into the two-inch steaks we had requested. For $10.85 we had three pair of steaks for grilling and the end pieces for a fish stew.

On Thursday morning, Luis emailed with a quote on his used 18hp Tohatsu. He also told me that he needed to modify the transom of the dinghy by adding 2.5cm to the top of it so that the motor would be at its perfect depth. He added: "We raise transoms all the time, will need to cut middle strake (on top transom) open it a bit, drill 3 holes to place wooden stuckos and raise the transom with fiber glass, let it dry, sand a bit, re paint, and screw both front/rear engine plates to a higher transom position than before". I told him to proceed.

Also on Thursday morning we received an email from Gonzalo telling us that our wine order for three additional cases of Rafael Picasso's wines would be delivered to his house during the day, and that he could deliver it to us on the weekend. He forwarded the banking particulars for our direct deposit to Bodegas Vista Alegre's account. We had found the wines so outstanding that we couldn't leave without buying more. Unlike my experience with much of the rest of the wine world, the prices from the winery here are considerably less expensive than they are in the supermarkets. In other places, the prices at the winery are almost always higher than in the supermarkets, since the producers do not want to under-cut their distribution chain.

I opened-up the back of the main 12-volt distribution panel and examined the plate of spaghetti, trying to make sense of it. Also I needed to plan my cable runs from the 210 amp alternator to the house bank, and to include the start batteries for the main engine and the generator. My simplest approach would be to connect to the same terminals as the generator, since its nominal rating is 280 amps with a continuous output of 220 amps, so quite similar to the 210 amps of the Balmar.

I began working on the cables, fitting the terminals onto the ends of the 3/0 gauge that Edi had hauled back from Vancouver in her luggage. I tried without success to replicate a crimper with the internal articulations of our bolt cutter. I'm going to have to either find a proper crimper or take the wires ashore and use a heavy hammer and a punch with concrete slab as an anvil. I need to take the wires ashore anyway, to see if our 220 volt 100 amp soldering gun can generate enough heat in the terminal and wire to draw-in some solder.

On Thursday evening I seared a pair of fresh bonita tuna steaks and served them with basmati rice and freshly shucked peas with sauteed portobello mushrooms, shallots and garlic, garnished with Roma tomatoes with a sprinkle of basil. With it we enjoyed Cava Cordon Negro from Frexinet.

Mid-morning on Friday we grabbed a bus along La Marina and after more than hour, got off on Prado at Araquipa, north of Miraflores. We walked the 3.7 kilometres down to Angamos and along it into the suburb of Surquillo a tiny shop at 1019 called Pernoshow. We were told it had a broad selection of stainless steel hardware, including milimetricos, which we had thus far not been able to find in Peru. They had open stock of what we wanted, and we walked away satisfied.

We walked west back along Angamos for two kilometres to Huaca Pucllana, the partly restored ruins of a pyramid thought to have been built by the Lima Culture about fourteen to nineteen hundred years ago. It was mid-afternoon and our breakfasts had long since worn-off, so we stopped at La Bodega de la Tratoria, an Italian-style restaurant near the entrance to the ruins. We ordered two personal-sized pizzas, a prosciutto and an Italian sausage, and they were both delicious.

For S/10 each we bought tickets for a guided tour of the ruins. We learned that excavation began on the site in 1981, after two-thirds of it had been destroyed and built-over as Lima expanded. The preserved lands include the entire pyramid and several surrounding plazas. The construction technique was layer upon layer of small adobe bricks, placed vertically like books on a shelf. The site is surrounded on all sides by the up-scale homes of Miraflores.

The adobe bricks were made from local materials, and there were dioramas showing the method of brick making. The clay was mixed by foot, and the bricks were individually hand-formed, as indicated by the remaining finger marks. From the bleached, starched and ironed clothing the brick-makers were wearing, we gathered that the Lima Culture had a highly evolved laundry service.

The Lima Culture used the pyramid and its surrounding plazas for religious ceremonial purposes. Some fourteen hundred years ago the Lima Culture suffered internal crises and was over-run by the Wari Empire from Ayacucho to the southeast. The ceremonial uses of the site ceased, and it became a burial place for Wari elite.

There was also a display depicting a ceremony. We learned that the main ceremonies centered on remodelling the structures, having banquets of shark meat, breaking ceramic jars and sacrificing women and children. With these last activities, we thought it a good thing that the culture was overrun.

We finished the tour and walked back through residential areas and along the boulevard walkway up the centre of Arequipa to Prado, where we caught a bus to La Punta. We arrived back aboard Sequitur shortly after 1800, after an eight-hour excursion for stainless steel nuts, bolts and washers. Of this we spent two-and-a-half hours on buses for a total fare of S/6, and we walked a bit over eight kilometres. We were tired.