The Voyages of s/v Silverheels III

...a virtual ship's logbook, and some thoughtful (unabashed?) reflections on our sea-going experiences.

04 November 2017 | Somewhere in the Eastern Caribbean

18 October 2017 | Le Marin, Martinique in the French West Indies

25 January 2017 | Gosier, Guadeloupe

19 January 2017 | Le Gosier, Guadeloupe

19 January 2017 | Le Gosier, Guadeloupe

19 January 2017 | St Pierre, Martinique

06 January 2017

01 January 2017 | Fort Du France, Martinique

28 December 2016 | Grand Anse d'Arlet, Martinique

24 December 2016

14 November 2016 | St Anne, Martinique

06 October 2016 | St Anne, Martinique

04 October 2016

20 July 2016 | Rodney Bay, St Lucia

15 June 2016

15 June 2016

13 June 2016

13 June 2016 | Grand Anse d'Arlets

13 June 2016 | Grand Anse d'Arlets

09 May 2016 | Deshaies, Guadeloupe

Tickled Pink About being Occasionally Blue

02 March 2014 | Simpson Lagoon, St. Martin

Lynn

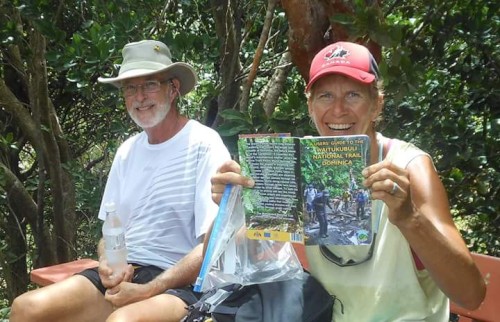

Lynn is enjoying some well deserved rest after a full day of renovating our anchor chain locker. She also received a pedicure from her loving crew.

'Silverheels III' was designed with one anchor locker, but has a bow roller for two anchors. We like the redundancy of being able to deploy one of two anchors (twice we have deployed both anchors at the same time) when we need to. With our Delta anchor, we occasionally had to put the Bruce down, as the bottom was too soft for the plow to get a grip. Go figure, it took centuries for our species to develop a plow for cutting through soil, but then somebody figures it would make a good design for an anchor. But it worked about 90% of the time for us. With our new anchor (a Rocna, for those who care), we feel that it is still good to have a second anchor ready to go, just in case something happens to the primary anchor... we just don't anticipate having to use it often (at all?).

The problem with one anchor locker is that it really doesn't provide a place for the second anchor rode. Messing around attaching a rode in an emergency seems like a bad idea to us; when you need it, it is generally a case of you need it NOW. Before we left Toronto, a member of the Niagara owners' group wrote about how he did a renovation on the anchor locker to make a two-tier system, which involved PVC pipe down to a storage area in the bow. We emulated this system, requiring a day or two of me fitting wood into the anchor locker, fitting the PVC pipe, fiberglassing (after grinding the paint a bit on the interior of the hull), fitting in the three shelves required for this system, and generally doing what is considered a "blue" job on the boat.

Now, a "blue" job may have something to do with the colour the air turns around you with the messiness/complexity or just lousiness of the job, but it tends to refer to "pink and blue" jobs. You know, "guy" jobs are blue, "chick" jobs are pink. This is a fairly normal division of labour on many boats, but it doesn't really suit us all of the time. Sure, I cook and do some of the cleaning, but that is because I am the better cook (Ken does the dishes and often cleans the head). I am the "coatings application specialist" on the boat, a term borrowed from Ryerson that referred to the painters, but they also did caulking and other coatings applications as part of their job. That is my territory as well. Epoxying, fiberglass work, paint, caulking, this all falls into my area of expertise. This means that I may have to glass in a bulkhead or the fiberglass engine mounts, or I may have to patch the dinghy. I do the research on bottom paint and am the project manager with those jobs, whether we do the work or have it farmed out. If the job requires brute strength or boat yoga (bending into awkward positions), I often do those jobs, too, being a little younger and slightly more flexible.

So, yesterday, as I continued the purge and cleaning and rearranging of the forward storage area of the boat, adjacent to the anchor locker, I got to eyeballing the access to the anchor locker. Ken and I have not been overly thrilled with the set up that we have, as it requires Ken to "break down" the anchor chain whenever we haul anchor. This is a nuisance, and it means nobody is at the helm; a situation we don't feel comfortable with if the anchorage is a little crowded or the wind is blowing like hell. We have been discussing another renovation of the anchor locker, which would put the secondary rode a little farther away (but still instantly deployable) and would mean we wouldn't have to break down the primary, all chain, rode. I took a look at the access I now enjoyed to that anchor locker and decided to take the bull by the horns. Crowbar, mallet, drill set, screw drivers, jigsaw, and grim determination were all gathered and readied for the job. I didn't even tell Ken what I was up to. He was working on some of "his" projects in the cockpit (some woodwork and electrical stuff). This was going to be a boat yoga kind of job, with a little brute strength thrown in. This was a "Lynn" job.

It took me three hours of shifting a grand total of 350 feet of chain (a couple of times), unscrewing, cutting, swearing, sweating (a lot of sweating), prying, wedging, dirt and dismantling (generally in an less than ideal position) to get phase one of the job done. So while the secondary rode isn't as accessible right now, we no longer need to break down the primary rode when we haul anchor. Phase two won't be as bad, and will require a little more thought as to how we will do it. But the worst of it is done.

Jobs get done on our boat according to ability and strengths. I have cleaned the fuel filter on the outboard as well as changed the spark plugs. Oil changes and fuel filter changes, as well as pre-departure engine checks are all jobs I can do, and have done, just like the transmission oil. I have run what has felt like miles of cable on our boat, as well as plumbing hose. Filling the diesel and water tanks tends to fall to me. And I can still bake bread, make a wicked dessert, and wash the floor. Ken's strengths are far more technical, which is fine by me - I'll run the wire, just don't ask me to hook it up if Ken is around! He is a professional with a soldering gun, and can wire together anything on the boat we can dream up, and strips the sheets on laundry day.

I think I'll get Ken to cut my hair a little later, after I do the check up on the diesel.

'Silverheels III' was designed with one anchor locker, but has a bow roller for two anchors. We like the redundancy of being able to deploy one of two anchors (twice we have deployed both anchors at the same time) when we need to. With our Delta anchor, we occasionally had to put the Bruce down, as the bottom was too soft for the plow to get a grip. Go figure, it took centuries for our species to develop a plow for cutting through soil, but then somebody figures it would make a good design for an anchor. But it worked about 90% of the time for us. With our new anchor (a Rocna, for those who care), we feel that it is still good to have a second anchor ready to go, just in case something happens to the primary anchor... we just don't anticipate having to use it often (at all?).

The problem with one anchor locker is that it really doesn't provide a place for the second anchor rode. Messing around attaching a rode in an emergency seems like a bad idea to us; when you need it, it is generally a case of you need it NOW. Before we left Toronto, a member of the Niagara owners' group wrote about how he did a renovation on the anchor locker to make a two-tier system, which involved PVC pipe down to a storage area in the bow. We emulated this system, requiring a day or two of me fitting wood into the anchor locker, fitting the PVC pipe, fiberglassing (after grinding the paint a bit on the interior of the hull), fitting in the three shelves required for this system, and generally doing what is considered a "blue" job on the boat.

Now, a "blue" job may have something to do with the colour the air turns around you with the messiness/complexity or just lousiness of the job, but it tends to refer to "pink and blue" jobs. You know, "guy" jobs are blue, "chick" jobs are pink. This is a fairly normal division of labour on many boats, but it doesn't really suit us all of the time. Sure, I cook and do some of the cleaning, but that is because I am the better cook (Ken does the dishes and often cleans the head). I am the "coatings application specialist" on the boat, a term borrowed from Ryerson that referred to the painters, but they also did caulking and other coatings applications as part of their job. That is my territory as well. Epoxying, fiberglass work, paint, caulking, this all falls into my area of expertise. This means that I may have to glass in a bulkhead or the fiberglass engine mounts, or I may have to patch the dinghy. I do the research on bottom paint and am the project manager with those jobs, whether we do the work or have it farmed out. If the job requires brute strength or boat yoga (bending into awkward positions), I often do those jobs, too, being a little younger and slightly more flexible.

So, yesterday, as I continued the purge and cleaning and rearranging of the forward storage area of the boat, adjacent to the anchor locker, I got to eyeballing the access to the anchor locker. Ken and I have not been overly thrilled with the set up that we have, as it requires Ken to "break down" the anchor chain whenever we haul anchor. This is a nuisance, and it means nobody is at the helm; a situation we don't feel comfortable with if the anchorage is a little crowded or the wind is blowing like hell. We have been discussing another renovation of the anchor locker, which would put the secondary rode a little farther away (but still instantly deployable) and would mean we wouldn't have to break down the primary, all chain, rode. I took a look at the access I now enjoyed to that anchor locker and decided to take the bull by the horns. Crowbar, mallet, drill set, screw drivers, jigsaw, and grim determination were all gathered and readied for the job. I didn't even tell Ken what I was up to. He was working on some of "his" projects in the cockpit (some woodwork and electrical stuff). This was going to be a boat yoga kind of job, with a little brute strength thrown in. This was a "Lynn" job.

It took me three hours of shifting a grand total of 350 feet of chain (a couple of times), unscrewing, cutting, swearing, sweating (a lot of sweating), prying, wedging, dirt and dismantling (generally in an less than ideal position) to get phase one of the job done. So while the secondary rode isn't as accessible right now, we no longer need to break down the primary rode when we haul anchor. Phase two won't be as bad, and will require a little more thought as to how we will do it. But the worst of it is done.

Jobs get done on our boat according to ability and strengths. I have cleaned the fuel filter on the outboard as well as changed the spark plugs. Oil changes and fuel filter changes, as well as pre-departure engine checks are all jobs I can do, and have done, just like the transmission oil. I have run what has felt like miles of cable on our boat, as well as plumbing hose. Filling the diesel and water tanks tends to fall to me. And I can still bake bread, make a wicked dessert, and wash the floor. Ken's strengths are far more technical, which is fine by me - I'll run the wire, just don't ask me to hook it up if Ken is around! He is a professional with a soldering gun, and can wire together anything on the boat we can dream up, and strips the sheets on laundry day.

I think I'll get Ken to cut my hair a little later, after I do the check up on the diesel.

Comments

| Vessel Name: | Silverheels III |

| Vessel Make/Model: | Hinterhoeller, Niagara 35 Mk1 (1979) |

| Hailing Port: | Toronto |

| Crew: | Lynn Kaak and Ken Goodings |

| About: | After five summers and winters living on our boat in Toronto Harbour, we've exchanged those cold Canadian winters for Caribbean sunshine. "Nowadays, we have ice in our drinks, not under the boat." |

| Extra: |

The completely biased and unabashed musings from the crew of Silverheels III

Who: Lynn Kaak and Ken Goodings

Port: Toronto