Little Boat, Big Dreams

Now, only have Bristol 24 -- Sanderling.

11 February 2010

02 January 2010

15 October 2009

20 September 2009

07 September 2009

29 June 2009

25 May 2009

27 April 2009

01 February 2009

28 November 2008

15 November 2008

15 September 2008

07 September 2008

30 August 2008

30 April 2008

15 April 2008

01 November 2007

01 August 2007

15 July 2007

25 June 2007

Motor is playing "hard to get..."

16 July 2023

Lawrence Bird

I’ve been arguing with my 6hp Tohatsu. The previous owner always seemed to have a bit of frustration starting it when cold, and I recall on my trip moving the boat that it didn’t want to wake up any of the mornings – in one instance when I had a small tug blaring its horn in my ear to get moving. But most write-up say the motor is trustworthy and near bullet proof.

In any case, I’ve ordered new filters, new spark and even have a new carburetor if it comes to that. It appears that fuel delivery (and losing prime) is an occasional bugaboo, so I’m heading down the path of ensuring that there is fuel. Hopefully that’s all that is ailing it, but it is wearing out my right arm pulling on the pull-cord

In any case, I’ve ordered new filters, new spark and even have a new carburetor if it comes to that. It appears that fuel delivery (and losing prime) is an occasional bugaboo, so I’m heading down the path of ensuring that there is fuel. Hopefully that’s all that is ailing it, but it is wearing out my right arm pulling on the pull-cord

Sanctuary has a new owner.

01 May 2023

Lawrence Bird

Sort of a bitter-sweet moment, but two boats were just too much of a good thing for the ol' fat-guy. It took a while to find the right buyer, but Sanctuary is now sold; although I'd guess it will be several months before she's back in the water.

The new owner has major fabrication skills and appears to be looking forward to tackling the projects needed to get Sanctuary sailing again -- some of the projects were caused by her unexpectedly long sojourn on dry land and of course some of them stem from the items that surprised us right after purchasing her. I trust this time she goes back in the water, she'll be ready for it.

The new owner has major fabrication skills and appears to be looking forward to tackling the projects needed to get Sanctuary sailing again -- some of the projects were caused by her unexpectedly long sojourn on dry land and of course some of them stem from the items that surprised us right after purchasing her. I trust this time she goes back in the water, she'll be ready for it.

Small Projects over the Winter

09 February 2023

Lawrence Bird

Sanderling, the B24's name for now has spent the past couple of months in slip at the boatyard off the Great Wicomico river.

The seller told me at the outset that the old solar-charger on the engine hatch was not working, so I purchased a small, 12-watt, charger and simply taped it in the cockpit to help keep the battery alive over the winter, as well as providing a bit of juice for the occasional use of the tiny bilge pump. Good thing because we've had all sorts of rain, occasionally nearly torrential, and the boat has taken on enough water that I to run the pump for 20-30 seconds every week or so to dry out the bilge.

Beyond that, the only really discernible projects have amounted to crawling around the boat and looking into various nooks and crannies to see what it looks like. I did slather on some G-Flex on the cracked cockpit seat (was cracked by previous owner) to help slow down any leaks there, but the seat hatched will eventually be replaced or perhaps reconfigured altogether, and this just buys a bit of time.

As soon as it warms enough, I'll install the deck-pipe so the anchor chain/rode can be sent into the locker in the bow. Because of intermittent windy conditions, the only real task has been to ensure that the mooring lines aren't chaffing -- typical stuff.

The seller told me at the outset that the old solar-charger on the engine hatch was not working, so I purchased a small, 12-watt, charger and simply taped it in the cockpit to help keep the battery alive over the winter, as well as providing a bit of juice for the occasional use of the tiny bilge pump. Good thing because we've had all sorts of rain, occasionally nearly torrential, and the boat has taken on enough water that I to run the pump for 20-30 seconds every week or so to dry out the bilge.

Beyond that, the only really discernible projects have amounted to crawling around the boat and looking into various nooks and crannies to see what it looks like. I did slather on some G-Flex on the cracked cockpit seat (was cracked by previous owner) to help slow down any leaks there, but the seat hatched will eventually be replaced or perhaps reconfigured altogether, and this just buys a bit of time.

As soon as it warms enough, I'll install the deck-pipe so the anchor chain/rode can be sent into the locker in the bow. Because of intermittent windy conditions, the only real task has been to ensure that the mooring lines aren't chaffing -- typical stuff.

Old Fat-Guy Makes it in Spite of Himself

07 November 2022

Lawrence Bird

Well, the "short" of it is that after a few miscalculations, geriatric embarrassments and what have you, the B24 is safely in its new home at Jennings Boatyard in Reedville, VA. The lessons are many but primarily; [1] a sailor should allow enough time to learn the essentials of the boat (especially the equipment aboard), [2] start with enough time for the planned trip and of course [3] plan your steps in advance as much as possible.

The third item is especially important for a solo sailor, regarding planning in advance, since on a small boat with no self steering it is not feasible to spend lots of time at the chart-table (yep, this little B24 has one). I felt I'd made a good stab at planning ahead -- at least as far as weather and navigation -- had spent an evening studying the chart and identifying the GPS track/route/waypoints for the expected 120 nm trip, and had them all logged into the Garmin 78sc and foresaw no issues there. The other items were more a matter of "haste makes waste...," or nearly so.

My initial error was that I was largely unprepared because I started out from Williamsburg almost a day and a half later than I'd originally allowed for, and since I felt had a semi-hard arrival time to be at my work early Monday morning, I felt couldn't easily extend/delay. More on that later (perhaps), but by starting off from Williamsburg later than I'd planned meant a day and a half boring motor-sailing down the James river; following buoy after buoy to Willoughby Bay.

Willoughby Bay is in the middle of one of the eastern US's busy naval ports and is an often used anchoring spot for civilian pleasure-boats transiting through the Newport News/Norfolk area. Two days of mild, almost windless conditions from Williamsburg, with official weather predictions of more lazy down-wind motor-sailing, lulled the geriatric skipper (who a week later turned seventy-five) into complacency. I found myself half-snoozing in the cockpit on a sunny, mild Saturday morning, making lazy course adjustments to avoid ever-present commercial shipping and tugs with tows of barges, as well as occasional naval vessels.

The fly in the ointment was my gross unfamiliarity with the boat, indeed the previous owner had actually hanked on the sails in an effort to get me going more quickly -- trying to be helpful. I'd owned a B24 for some years previously, so had confidence in the overall design, but this particular boat and its equipment were brand new to me. Indeed, we got to the boat at Williamsburg, installed a new battery, threw my duffels on and was on my way in less that forty-five minutes (as noted; haste makes waste... probably a lesson there somewhere). And, as I was to find out, the fact that there was no stowage for the oversized anchor (Bruce/claw type -- apparently exceptional holding, but very, very heavy for these geriatric arms), nor a haus/deck pipe to lead the rode below deck; meant the whole affair just sat in a loose pile of chain and anchor on the foredeck where the previous owner had piled it.

But, what the heck -- it was a sunny, almost windless day, what's the issue?

This lack of anchor stowage is clearly un-seaman like, but the arrangement wasn't of much consequence, until two days later on Saturday (Shabbat) afternoon about halfway up the Bay, when the wind piped up, gusting to about double the forecasted 12-15 kts, and in one of the rolls when the semi-alert skipper was inattentive, the anchor, chain and the whole shooting match went over the side -- although all still tied to a bow-cleat... at that point I was still sailing downwind (more like bounding in 2-4 foot, occasionally breaking chop), but it was now blowing 20 something, gusting to 30 with sunny skies, accompanying by singing in the rigging (I later checked the buoy data, so these numbers aren't just a figment of white-knuckled, paranoid imagination); thankfully this loss of the heavy anchor and 75-plus feet of chain all happened in deeper water in mid-Bay and the boat's downwind speed apparently made it stream, so it didn't grab the bottom, but had to cut it free. Even at anchor I was nearly pooped just pulling it in, and by now this old skipper was far too exhausted at that point to drag it all back aboard -- the Creator guided the boat since I was occupied freeing the ground tackle from where it was entangled.

After all this, I heard a rattling, clanging commotion in the motor-well and eventually noticed that auxiliary outboard motor had come loose (although it had been puttered contentedly for two days, it was apparently not firmly clamped down -- thankfully it was not running once the wind piped up) and was just rattling around in the well... so by dusk of Saturday, after a series of usually harmless operator errors, I found I had no anchor and no motor, and was zipping downwind with too much sail (using a "fishermen's reef" to keep things quieted down) at times apparently bumping above 8kts according to my GPS recorder; oh well.., it is a sailboat, and running downwind, the boat seemed edgy but largely happy, so all is well, right? So, sail the thing...

The Father is good and He got me through to Reedville okay, by about 02:00 -- now with a list of several forthcoming modifications; some of them quite necessary, some just because I think they'd be neat.

But, not to keep folks in suspense -- all's well, and the Bristol is safely in a slip... but once again I'd relearned one of the critical lessons of my earlier posts; the skipper's responsibility, even when solo, is absolute!

The third item is especially important for a solo sailor, regarding planning in advance, since on a small boat with no self steering it is not feasible to spend lots of time at the chart-table (yep, this little B24 has one). I felt I'd made a good stab at planning ahead -- at least as far as weather and navigation -- had spent an evening studying the chart and identifying the GPS track/route/waypoints for the expected 120 nm trip, and had them all logged into the Garmin 78sc and foresaw no issues there. The other items were more a matter of "haste makes waste...," or nearly so.

My initial error was that I was largely unprepared because I started out from Williamsburg almost a day and a half later than I'd originally allowed for, and since I felt had a semi-hard arrival time to be at my work early Monday morning, I felt couldn't easily extend/delay. More on that later (perhaps), but by starting off from Williamsburg later than I'd planned meant a day and a half boring motor-sailing down the James river; following buoy after buoy to Willoughby Bay.

Willoughby Bay is in the middle of one of the eastern US's busy naval ports and is an often used anchoring spot for civilian pleasure-boats transiting through the Newport News/Norfolk area. Two days of mild, almost windless conditions from Williamsburg, with official weather predictions of more lazy down-wind motor-sailing, lulled the geriatric skipper (who a week later turned seventy-five) into complacency. I found myself half-snoozing in the cockpit on a sunny, mild Saturday morning, making lazy course adjustments to avoid ever-present commercial shipping and tugs with tows of barges, as well as occasional naval vessels.

The fly in the ointment was my gross unfamiliarity with the boat, indeed the previous owner had actually hanked on the sails in an effort to get me going more quickly -- trying to be helpful. I'd owned a B24 for some years previously, so had confidence in the overall design, but this particular boat and its equipment were brand new to me. Indeed, we got to the boat at Williamsburg, installed a new battery, threw my duffels on and was on my way in less that forty-five minutes (as noted; haste makes waste... probably a lesson there somewhere). And, as I was to find out, the fact that there was no stowage for the oversized anchor (Bruce/claw type -- apparently exceptional holding, but very, very heavy for these geriatric arms), nor a haus/deck pipe to lead the rode below deck; meant the whole affair just sat in a loose pile of chain and anchor on the foredeck where the previous owner had piled it.

But, what the heck -- it was a sunny, almost windless day, what's the issue?

This lack of anchor stowage is clearly un-seaman like, but the arrangement wasn't of much consequence, until two days later on Saturday (Shabbat) afternoon about halfway up the Bay, when the wind piped up, gusting to about double the forecasted 12-15 kts, and in one of the rolls when the semi-alert skipper was inattentive, the anchor, chain and the whole shooting match went over the side -- although all still tied to a bow-cleat... at that point I was still sailing downwind (more like bounding in 2-4 foot, occasionally breaking chop), but it was now blowing 20 something, gusting to 30 with sunny skies, accompanying by singing in the rigging (I later checked the buoy data, so these numbers aren't just a figment of white-knuckled, paranoid imagination); thankfully this loss of the heavy anchor and 75-plus feet of chain all happened in deeper water in mid-Bay and the boat's downwind speed apparently made it stream, so it didn't grab the bottom, but had to cut it free. Even at anchor I was nearly pooped just pulling it in, and by now this old skipper was far too exhausted at that point to drag it all back aboard -- the Creator guided the boat since I was occupied freeing the ground tackle from where it was entangled.

After all this, I heard a rattling, clanging commotion in the motor-well and eventually noticed that auxiliary outboard motor had come loose (although it had been puttered contentedly for two days, it was apparently not firmly clamped down -- thankfully it was not running once the wind piped up) and was just rattling around in the well... so by dusk of Saturday, after a series of usually harmless operator errors, I found I had no anchor and no motor, and was zipping downwind with too much sail (using a "fishermen's reef" to keep things quieted down) at times apparently bumping above 8kts according to my GPS recorder; oh well.., it is a sailboat, and running downwind, the boat seemed edgy but largely happy, so all is well, right? So, sail the thing...

The Father is good and He got me through to Reedville okay, by about 02:00 -- now with a list of several forthcoming modifications; some of them quite necessary, some just because I think they'd be neat.

But, not to keep folks in suspense -- all's well, and the Bristol is safely in a slip... but once again I'd relearned one of the critical lessons of my earlier posts; the skipper's responsibility, even when solo, is absolute!

Well, what's old is new -- to me at least

27 October 2022

Lawrence Bird

It appears that there may be another Bristol Corsair (B24) in my future. After letting Angels Wings go a few years ago (our previous Bristol 24) in a moment of haste, I've become increasingly sorry over the intervening time not to have her. Wings was a solid sailing boat, but esthetically she was no prize, and the ODay looked much cleaner (it is) and of course has probably twice the interior room of our B24.

The ODay 30 is a good boat, in decent condition and a well known design with few unknowns when sailing, but I've decided that I'll finish up the refurbishing of Sanctuary, our ODay 30, get her back in the water and then put her up for sale.

If all goes well, in the next few weeks we'll have a new-to-us Bristol 24, with fairly recent standing rigging and I am hopeful that she'll pick right up where Angels Wings left off.

More to follow -- watch this space.

The ODay 30 is a good boat, in decent condition and a well known design with few unknowns when sailing, but I've decided that I'll finish up the refurbishing of Sanctuary, our ODay 30, get her back in the water and then put her up for sale.

If all goes well, in the next few weeks we'll have a new-to-us Bristol 24, with fairly recent standing rigging and I am hopeful that she'll pick right up where Angels Wings left off.

More to follow -- watch this space.

Second thoughts

08 July 2022

Lawrence Bird

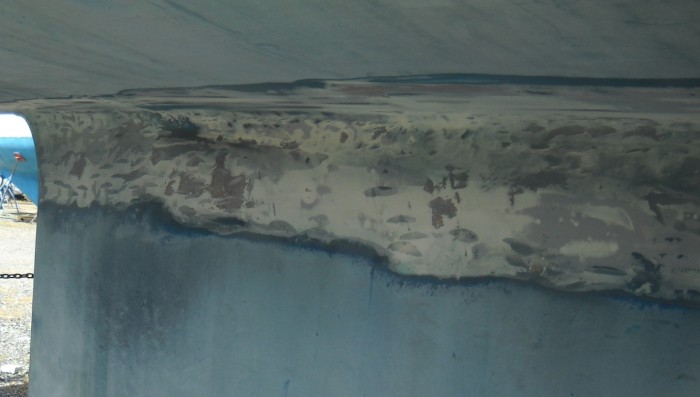

It's been awhile, but after chatting with some boat-builders (professionals), it appears that I probably should remove the gelcoat in the areas I plan to add glass and epoxy... given that strength is far more the issue that esthetics (for me, at least), I ordered a couple of 60grit abrasive wheels to hopefully speed the process of gelcoat removal, and then I can get back to the task at hand...

| Vessel Name: | Sanderling |

| Vessel Make/Model: | Bristol-24 |

| Hailing Port: | Colonial Beach, Virginia, USA |

| About: | |

| Extra: | The skipper went out and found another Bristol 24 -- this one, Sanderling, is mechanically in better shape than Angels Wings, with newer rigging and motor, but still a small basic boat with no pretentions about high-society. |

Gallery not available

Port: Colonial Beach, Virginia, USA