Kaimusailing

s/v Kaimu Wharram Catamaran

| Vessel Name: | Kaimu |

| Vessel Make/Model: | Wharram Custom |

| Hailing Port: | Norwalk, CT |

| Crew: | Andy and the Kaimu Crew |

| About: | Sailors in the Baltimore, Annapolis, DC area. |

17 April 2024 | St Marys, GA

Dinghy Skeg

I was suffering with what seemed like a cold and also had allergy symptoms. I awoke and felt fine. The green pollen that was coating everything was gone. Maybe it will return.

07 April 2024 | St. Marys, GA

Clammy Hands

Items came in from TEMU, the Chinese cut rate retailer. One was a nice little drone that cost about twelve and a half dollars. It looked like an easy thing to play with while I coughed and sneezed. I was fighting a summer cold, even though it is not summer elsewhere, it seems like it here. A nice [...]

02 April 2024 | St. Marys, GA

Sun Doggie

After laminating the cedar strips onto the gunwales of the dinghy I found the screws I used wouldn’t come out. The epoxy had seized them. The screw heads were stripped so I cut a straight slot in the heads with the cut off wheel. The cedar smoked when the screw heads got red hot. I could remove [...]

21 March 2024 | St. Marys, GA

Just Add Water

The rainy weekend started off with overcast and fog but no rain. It looked like I might be able to get something done on the D4 dinghy. I wanted to change the bow seat which is really the bow deck. The sailing option uses the deck to hold the freestanding mast. I didn’t like how the deck looked, [...]

01 March 2024 | St. Marys, GA

D4 Dinghy Alternative Seats

The rain event was more wind than rain, strong winds with gusts up to 44 mph. We drove into town to see what the harbor was like. There was a small sailboat that had dragged anchor and was sitting close to shore. The tide was out. We left and played with Bleu at Notter’s Pond.

23 February 2024 | St. Marys, GA

D4 Inside Seams

Day two of the dinghy build started out with me finishing wiring the hull bottoms together on the centerline of the bottom panels. This was much easier than the wiring of the chine edges of the bottom panels and the side panels.

Proa Pt. II

.

The polynesians of old developed their proa designs over a long period of time and their methods included making and racing little models. This was a society that had no writing, so design was carried on to the next generation by oral tradition. The dimensions of the parts of the proas had an exact relationship that was measured by a stick or twine. Although the general design of these proas was similar at islands thousands of miles apart, there were modifications to match the local environment.

.

We will also make a model to confirm the design before making a full size proa. A "virtual" boat will be designed on the computer to help make a successful model without too many generations. Fortunately we don't have the constraints of building materials and methods that dictated much of the old polynesian design.

.

The old polynesian proa evolved from a canoe hollowed out from a log. If there were no big logs available, it would be impossible to make a canoe. Also, the dimensions of the canoe would be limited, such as low freeboard, and they would not be seaworthy, they would be restricted to use near shore. At some point a breakthrough in contruction technique allowed planks to extend the freeboard and made a seagoing canoe possible. There were no metal tools or modern glues. The method of fastening planks together evolved to a technique of drilling holes and tying planks together with fibers and sealing them with plant pitch.

.

Modern canoes can be built with the stitch and glue technique, in a way similar to the ancient polynesians, but much more easily with modern tools and glues. A company that specializes in stitch and glue designs and kits is Chesapeake Light Craft. They offer a couple of proas which have been prototyped and tested. We will use some of their ideas in our design. Their design evolved from the work of Russell Brown, whose father, Jim Brown, is a modern designer who developed trimarans.

.

Because we want to make a craft that can be disassembled and packed away like a folding kayak, some design parameters are imposed that the ancient polynesians would not have considered. Folding kayaks have adopted a cross section shape that is flat on the bottom and has a shallow draft. The bottom consists of a flat floor board that holds its shape against water pressure better than the skin on frame structure of the rest of the kayak. So we will also use a flat bottom design. There are many examples of flat bottom outrigger canoes and proas. In the old days about a hundred years ago, one of Capn Nat Herreschoff's buddies, Commodore Ralph Munroe, designed and tested several flat bottomed proas on Biscayne Bay in Florida. He also worked with the design type called "Sharpie".

.

My Folbot has 4 pieces of floor board that hinge together end to end. It's like an accordian. The boat is assembled on shore by putting together the framework of the stem and stern, then forcing those frameworks into the hull outer skin. As the boat framework is pushed into the ends of the skin, the middle floorboards swing into place downwards, hinged together, and force the boat into a tight fit. Additional frames and longitudinal pieces are put together in the middle sections of the boat to complete the skin on frame structure with some locking pieces to keep it together. There are videos on YouTube of folding kayak assembly of different brands, including Folbot and Keppler.

.

The skin on frame structure uses the tension of the skin and the compression strength of the frame to hold its shape. The forces on a paddling kayak are not the same as those on a sailing proa. The sailing rig puts additional loads similar to a bow and arrow with the hull being the bow and the mast the arrow. Traditional proas used a crab claw sail, which is similar to a lateen sail, and a mast that can tip fore and aft. The tack of the sail, where the two lateen yards come together at the front of the sail, is secured at the bow. The mast is stepped amidships and leans forward attached to the upper yard. When the proa changes tacks, the tack is removed from the bow and brought to the stern. The yards are eased downwind away from the mast, and when the tack has been secured at what had been the stern, the yards are sheeted in at what had been the bow. The old stern becomes the new bow and the old bow becomes the new stern. The outrigger is always kept upwind. Diagrams of this procedure are available on the clcboats.com website.

.

The sailing rig design will be tested on the model and won't be tacking or shunting, just sailed on one course. Because the proa configuration is supposed to be inherently self steering, the model will be used to set up sail and hull balance. The model will not be designed to fold up like a folding kayak, it will be built skin on frame though.

.

Sharpie hull design is very simple and quickly developed using our computer hull design programs. The deck and topsides of our proa are more difficult to shape. The Munroe proas had flat sides and flat deck, very simple. The Chesapeake Light Craft proa has a swoopy Dick Newick kind of shape with nearly plumb bows and a reverse sheer. Folding kayaks usually have a tiny bow with reverse sheer or at least a crowned deck profile. Recent catamaran designs have been using something called "wave piercing" design in the bow. Instead of a flat deck, it is sharply crowned to prevent water piling up on the foredeck when running into a wave. The Oracle 72 foot America's Cup catamaran showed that this design feature can fail. They did a spectacular pearl dive into the waves, cartwheeled, and totalled the huge catamaran. Because this type of bow is easily adaptable to skin on frame, we will use it, but not to the extreme of the big America's Cup boats.

.

The midships of the proa is going to end up as a boxy shape on the bottom and the deck will be open, like the Folboat Greenland II design, or the larger Klepper designs. Our calculations from the hull shape computer programs show a very narrow hull. Freeboard should be around 1 1/2 feet or so. The boxy shape works well to withstand the loads imposed by the ends of the hull hitting waves and the crew hopping around attempting the tacking maneuver.

.

The beauty of the Pacific proa is that the outrigger doesn't have to be strong enough to support the drive of the sail rig because it is always to windward. This reduces weight and reduces the strength requirement of the crossbeams. The crossbeams do have to support the crew when necessary, and it would be nice to be able to have a small igloo tent there when at anchor, enabling overnight camping trips. Once again, the model will have a simple outrigger. Chesapeake Light Craft proas have a daggerboard in the outrigger, but this can easily be tried out with the model. Hopefully it won't be necessary. The need for some sort of leeboard or daggerboard will be determined by trial and error on the model.

.

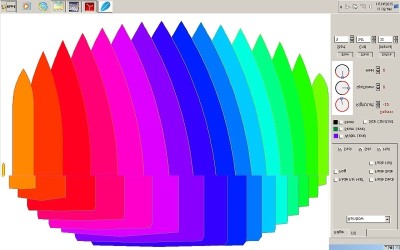

The picture is of some Bearboat rendered hulls that have been colorized and represent approximations of the hull shape of the proa. It looks a lot like it's upside down, but it is a flat bottomed planing hull with wave piercing deck. It wasn't possible to accurately line up the frames, top and bottom, without a lot more work to fine tune, and the sharply cambered deck will only be used in the stem and stern, the central part of the hull will have vertical sides. It would be very easy to make the model just by bending hull panels and cut to fit, but the computer programs calculate wetted surface and displacement and generate the important dimensions of beam and draft at each frame.