MAKING OUR DREAM OUR ADDRESS

01 November 2017

15 February 2016 |

08 May 2015

14 February 2014

15 January 2012

09 September 2010

02 September 2010

01 September 2010

01 June 2010

02 October 2000

01 October 2000

INTO THE WATER!

01 November 2017

PERSISTENCE, PATIENCE & DETERMINATION!

Nov 13, 2017 she went into the water. It was such an exciting day! She was trailored into Schooner Creek in Portland from Scappoose Or. We followed behind in our car. It was emotional as she is our baby!

All went very well. (There are videos & photos of the day in the photo gallery). From the lift they finally lowered her into the water. Mark was holding his breath but as she hit the water it was apparent that 'all was well!!

Hold on Grace, it's going to be OK!

Nov 13, 2017 she went into the water. It was such an exciting day! She was trailored into Schooner Creek in Portland from Scappoose Or. We followed behind in our car. It was emotional as she is our baby!

All went very well. (There are videos & photos of the day in the photo gallery). From the lift they finally lowered her into the water. Mark was holding his breath but as she hit the water it was apparent that 'all was well!!

Hold on Grace, it's going to be OK!

Buy a Project Boat???

15 February 2016 |

Buying an unfinished boat is not for everyone. On this boat some of the issues had not been resolved (at least not on paper). Two major issues were the bow sprit and the power transfer from the transmission to the propeller shaft.

Earl had designed part of it (the hardest part), but by itself it was incomplete. Fortunately, I was able to imagine the entire assembly and fabricate the entire belt drive system. They had purchased some of the parts the boat would eventually need, such as a spool of stainless rigging cable, Norseman fittings & bronze turnbuckles for the standing rigging. Many of the parts although 40+ years old and antiquated still looked new.

Some parts needed to be replaced as the winches for handling the sails. All in all, the boat will be a New Boat with very modern equipment with a 50 year old design.

So with the few things Mark mentioned above, everything else had to be purchased or made by hand. Mark is very talented and resourceful but everything takes so much time. And then there are all the times that life happens & you don't get to work on the boat like you would like to.

Earl had designed part of it (the hardest part), but by itself it was incomplete. Fortunately, I was able to imagine the entire assembly and fabricate the entire belt drive system. They had purchased some of the parts the boat would eventually need, such as a spool of stainless rigging cable, Norseman fittings & bronze turnbuckles for the standing rigging. Many of the parts although 40+ years old and antiquated still looked new.

Some parts needed to be replaced as the winches for handling the sails. All in all, the boat will be a New Boat with very modern equipment with a 50 year old design.

So with the few things Mark mentioned above, everything else had to be purchased or made by hand. Mark is very talented and resourceful but everything takes so much time. And then there are all the times that life happens & you don't get to work on the boat like you would like to.

Retirement!

08 May 2015

Woo Hoo! Retirement - now things will get done really quickly! More time, less restrictions. This will be easy! Wrong!!!! Mark said he just traded a job that he got paid for to a job with No pay & longer hours. On the bright side things are getting done faster.

If you have ever bench pressed a 13 ton boat, well at least that is what it felt like. After days & months of holding a sander to the bottom of the boat, that is how it felt. Did I mention that a 44 foot boat has a really large bottom. And 44 feet is only one side!!

Everything above the deck/hull joint was just raw fiberglass. All edges had to be sanded, filled and faired. Time was spent planning the deck hardware, hatches & rigging.

The entire cabin top has been cored with balsa wood. This means every hole made in the fiberglass must be cored (drilling out the fiberglass, remove the balsa wood & fill with fortified epoxy. Mark has done this process in over hundreds & hundreds of holes. Getting the top ready to paint and add hardware was not a fun easy process either.

My (linda) saving Grace is that Mark is able to maintain a very positive outlook. He is always saying "Piece of Cake" when I ask him how it is going. Amazing!!

If you have ever bench pressed a 13 ton boat, well at least that is what it felt like. After days & months of holding a sander to the bottom of the boat, that is how it felt. Did I mention that a 44 foot boat has a really large bottom. And 44 feet is only one side!!

Everything above the deck/hull joint was just raw fiberglass. All edges had to be sanded, filled and faired. Time was spent planning the deck hardware, hatches & rigging.

The entire cabin top has been cored with balsa wood. This means every hole made in the fiberglass must be cored (drilling out the fiberglass, remove the balsa wood & fill with fortified epoxy. Mark has done this process in over hundreds & hundreds of holes. Getting the top ready to paint and add hardware was not a fun easy process either.

My (linda) saving Grace is that Mark is able to maintain a very positive outlook. He is always saying "Piece of Cake" when I ask him how it is going. Amazing!!

Rescueing another boat that paid off

14 February 2014

So, at this point Mark has been working on "By His grace" for 4 years. This is all done after work & on weekends.

He has also been watching this boat down at the marina that in the process of sinking. The owner passed away & his children didn't want it. It is a 34 foot Catalina sailboat.

She was going up for auction & Mark thought he would wander down and see what was going on. Mark and one other man showed up. The harbor master wanted at least $1,800 for the unpaid moorage fees.

Other man bid $1,900. Mark bid $2,000. Other man decided Mark could have it! So, he comes home & tells me he bought another boat!!!!! Just what we need I'm thinking but then it isn't me doing all the work so OK.

It took one year of hard work....and it sold for $33,000!! So Mark went out & bought the electric winches he wanted, the traveler, roller furling for the two head sails, and other goodies that he had been drooling over.

Well, that took one year out of working on our Cascade. but, it did pay off.

He has also been watching this boat down at the marina that in the process of sinking. The owner passed away & his children didn't want it. It is a 34 foot Catalina sailboat.

She was going up for auction & Mark thought he would wander down and see what was going on. Mark and one other man showed up. The harbor master wanted at least $1,800 for the unpaid moorage fees.

Other man bid $1,900. Mark bid $2,000. Other man decided Mark could have it! So, he comes home & tells me he bought another boat!!!!! Just what we need I'm thinking but then it isn't me doing all the work so OK.

It took one year of hard work....and it sold for $33,000!! So Mark went out & bought the electric winches he wanted, the traveler, roller furling for the two head sails, and other goodies that he had been drooling over.

Well, that took one year out of working on our Cascade. but, it did pay off.

7. How do you eat a elephant?

15 January 2012

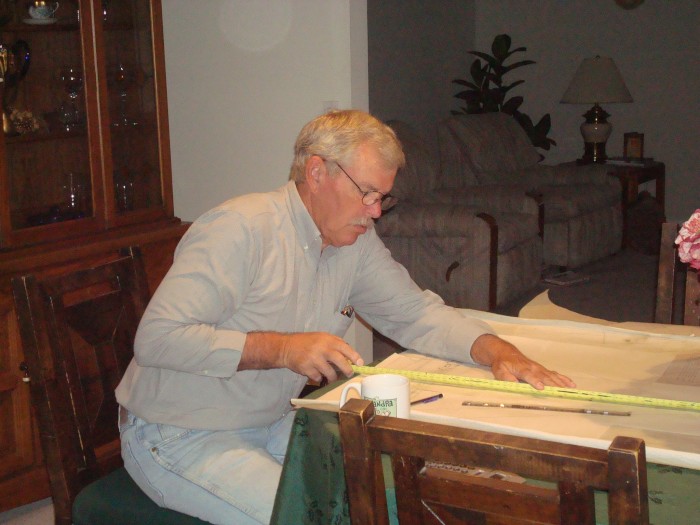

ONE BITE AT A TIME! Mark would spend hours at this table calculating & recalculating. Designing & redesigning. The amazing thing to me was he was always optimist & would say "Piece of Cake!!"

I was a "saint" (haha) and said he could put boat parts in the dining room. When he wasn't working at the boat he would work in our garage & made the hatch covers, bow sprit, and handrails. So he had wood projects going on & welding projects. All of these spilled over into our living room. We even had a brand new toilet & stove behind the couch. Saint - I know!!!

I was a "saint" (haha) and said he could put boat parts in the dining room. When he wasn't working at the boat he would work in our garage & made the hatch covers, bow sprit, and handrails. So he had wood projects going on & welding projects. All of these spilled over into our living room. We even had a brand new toilet & stove behind the couch. Saint - I know!!!

6. In the Scappoose Boatyard

09 September 2010

We now own a boat!! I don't think it is very pretty boat. It needs A WHOLE LOT OF WORK!! But she has a ton of potential. Mark says "She has pretty (graceful, beautiful) lines. "She is a diamond in the ruff."

There was a insurance commercial that starred a mother whose children bought a boat. She said "all they talk about is the BOAT! The BOAT, THE BOAT, THE BOAT!!!

So, we had the boat moved from Gresham to Dike's Marine & Storage in Scappoose Oregon. Working with Bruce and Debbie Helms has made this whole project possible. They are one of the few boatyards that will allow you to do your own work on your boat. Their help and resources are invaluable.

Well, that's the direction our lives took. Mark worked every weekend and worked work nights when it was still light outside. There was so much that needed to be redone due to sitting in the water and sitting unattended for the next 20 years.

The first thing Mark had to was to construct a storage cover to protect it from the rain because it wasn't water proof. It did leak! Not good.

He then chose to start working on the bottom of the boat, thinking that if he started with the nastiest job first everything else would be easy (wrong)! Anyway, all of the paint had to be sanded off. This sounds like a easy thing to do--just sand it off. Well.....

Then all the keel fairing had to be chiseled out and sanded then filled with the proper fairing material (fortified epoxy filler), sanded again and then painted with six coats of barrier coat and then six coats of COPPERCOAT bottom paint. COPPERCOAT claims to last up to 10 to 15 years, if it works as advertised it will justify the extra cost.

SEE MORE PHOTOS IN THE "BEGINNING" AND "BOTTOM" PHOTOS

There was a insurance commercial that starred a mother whose children bought a boat. She said "all they talk about is the BOAT! The BOAT, THE BOAT, THE BOAT!!!

So, we had the boat moved from Gresham to Dike's Marine & Storage in Scappoose Oregon. Working with Bruce and Debbie Helms has made this whole project possible. They are one of the few boatyards that will allow you to do your own work on your boat. Their help and resources are invaluable.

Well, that's the direction our lives took. Mark worked every weekend and worked work nights when it was still light outside. There was so much that needed to be redone due to sitting in the water and sitting unattended for the next 20 years.

The first thing Mark had to was to construct a storage cover to protect it from the rain because it wasn't water proof. It did leak! Not good.

He then chose to start working on the bottom of the boat, thinking that if he started with the nastiest job first everything else would be easy (wrong)! Anyway, all of the paint had to be sanded off. This sounds like a easy thing to do--just sand it off. Well.....

Then all the keel fairing had to be chiseled out and sanded then filled with the proper fairing material (fortified epoxy filler), sanded again and then painted with six coats of barrier coat and then six coats of COPPERCOAT bottom paint. COPPERCOAT claims to last up to 10 to 15 years, if it works as advertised it will justify the extra cost.

SEE MORE PHOTOS IN THE "BEGINNING" AND "BOTTOM" PHOTOS

| Vessel Name: | By His Grace |

| Vessel Make/Model: | Cascade 44 |

| Hailing Port: | Aloha, Or |

| Crew: | Mark & Linda Kloepfer |

| About: | |

| Extra: | We will be sailing Sailing Vessel "By His Grace" as well as Sailing By HIS Grace! |

By His Grace's Photos - Beginning pictures

Who: Mark & Linda Kloepfer

Port: Aloha, Or