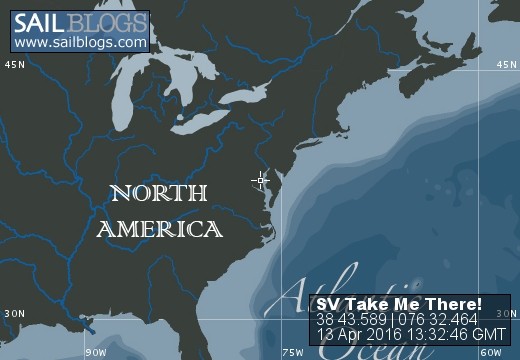

SV Take Me There!

A cruising boat/couple on an adventure!

08 March 2017 | Herrington Harbour South

31 January 2017 | Herrington Harbour South

24 January 2017 | Herrington Harbour South

05 January 2017 | Herrington Harbour South

20 December 2016 | Herrington Harbour South

07 November 2016 | Herrington Harbour South

01 November 2016 | Herrington Harbour South

31 October 2016 | Herrington Harbour South

24 October 2016 | Herrington Harbour South

20 October 2016 | Herrington Harbour South

14 October 2016 | Herrington Harbour South

21 September 2016 | Herrington Harbour South

15 July 2016 | Herrington Harbour South

30 June 2016 | Herrington Harbour South

17 June 2016 | Herrington Harbour South, Friendship MD

07 June 2016 | Herrington Harbour South, Friendship MD

27 May 2016 | Herrington Harbour South, Friendship MD

23 May 2016 | Herrington Harbour South, Friendship MD

16 May 2016 | Herrington harbour South, Chesapeake Beach, MD

02 May 2016 | Herrington harbour South, Chesapeake Beach, MD

Maintenance and Project Time! Hydraulics and Halyards and Heads - Oh My!!!

02 May 2016 | Herrington harbour South, Chesapeake Beach, MD

Rain/Wind

This past week was a maintenance week. We blew a seal on one of the davit hydraulic cylinders a while back. The aft black-water tank project started and we did some running rigging replacement. We had sailing on the schedule this week but Mother Nature had other plans (Sorry Fred). Looking forward to trying again next week.

The Davit Hydraulics Project: We have a nice beefy set of hydraulic davits - atop which sit our 530W solar array. The davits are a custom design of the previous owner built to lift a heavy RIB - which we would like very much to hang on them. While load-testing the lift capacity, I blew a seal on one of the lift cylinders thus beginning the task of repair or replacement. I decided to "replace" since the original cylinders were of the "welded" type (have to cut it open to service any seals) - deciding to go to a unit that was designed to be serviced with a cap-wrench. Cylinders arrived but the upper and lower cross-tubes had to be modified to fit the davit lift yokes...plus, the new cylinders have more lift capacity so the fluid couplers/fittings also have to be modified as well. The search continues for the right sized fittings and I hope to have parts on hand to accomplish reassembly within the week.

Musings on these projects had me chasing "squirrels" as I continually "cogitated" on improvements that would be wise investments:

- All that for 8 inches? To lift our RIB, the stroke on the cylinders had to be at least 8 inches. This would allow the davits to travel the appropriate distance (arc) to lift (and lower) our heavy 650 lb RIB. I considered hanging a 7-1 purchase block set from them to simply pull the RIB up to the arms but realized that the davit "arc" was designed to begin lifting the RIB (as it sat in the water) off of our swim platform finding that a "straight lift" from the full-up position on the davits would drag the RIB over the swim platform (hence the design had a purpose - to clear the platform as the lift commenced). Keeping the original design was going to be the right answer! The search for replacement cylinders was a long one (several weeks) - finally found a near-suitable fit from Prince Hydraulics (gotta love GOOGLE!) after discovering that repair would be equal or above the cost of replacement! Cylinder "stroke" and closed cylinder length to fit our rig was challenging - couldn't seem to find one (right stroke) with a "compatible" other (14" closed length)...but Prince had a "close-enough" option for which I was willing to make modifications. We are 2-weeks into the problem and the RIB is still not "lift-able!" The right fittings will do the trick...task #1 for this weeks lunch hour travels.

- A winch will still be nice? I still plan to put a winch on the davit-rig for a few reasons...first, to tighten up the RIB to the davit arms for stability instead of the harness just letting the RIB swing with motion. Still have to work out this math? Second...a winch would allow us to deploy a "kedge" anchor astern if we needed to pull ourselves off of a grounding. The winch (an ATV 2500 lb'er) will need to be modified (divide the winch drum into 2 x halves to pull from opposite directions) to accommodate the 2-point lifting bridle for the RIB. Either half can be used for kedging). The turning blocks will need to be sturdy enough to hold 650 lbs and we will use high-strength poly rope on the drum.

The Aft Holding Tank Project: The Admiral's nose is sensitive and she has prompted me to investigate the "musty" smell in the aft head (likely permeation of the old septic hoses). Since our new (to us) marina is an NDZ - we also needed to increase black-water tankage. Aforethought a few years ago prompted me to design (and have fabricated) an aft waste tank that would fit against the hull and give us around 20 gals of tankage to serve the aft head (which already has an MSD-1 at the ready). Living in an NDZ required me to "muse" upon the multi-functionality of the aft septic system. I wanted a 3-way capability: (1) Toilet to MSD-1 to overboard (when authorized); (2) Toilet to Overboard (when authorized); and (3) Toilet to tank to pump-out (legal all of the time). I decided to add a 4th capability... (4) Tank to overboard (with a second macerator pump) ... This permits us to fill the tank in an NDZ and dump it when we are far off-shore (such as visiting anchorages in protected environments like the Tortugas). During this project, we have also decided to replace the septic lines with the high-end non-permeable stuff to eliminate the penetration odors we often catch a whiff of during the summer season. We will do the forward head in mirror fashion adding tankage gages to both systems. The aft tankage is plumbed - I am ready to crack open the old septic lines for hose replacement and join the new tankage set-up to the existing system - but have been procrastinating...it's a "shitty" job but somebody has to do it (ME)!...so I've decided to do it while the Admiral is away on travel. PRAY for a clean (no spill) job PLEASE! The useful lesson learned is "don't scrimp" on septic hose. It is thick/stiff stuff! A heat gun is a must have for this project to soften it up and make tight, double-clamped connections!

Running Rigging Changes..."Yeah - but it's WIDE? Our jib, spinnaker and 3rd reef (main) lines were 5/8 inch double-braid. Although this "thick" line is pleasant to handle (over a thinner line), the gage of this rigging was heavy and would often "slow down" in the blocks or sheet-locks and "drag" on the gunnels in light winds (in the water). I replaced it with 5/16 inch double-braid and love it! The heavier stuff will be re-purposed to anchor rode for the stern anchor since each coil is 150 ft. Musings after replacing these lines are: Lighter is better (we will not likely stress tensile and stretch limits of the new lines) and lighter is faster (turning and locking cleat travel is now effortless).

The Davit Hydraulics Project: We have a nice beefy set of hydraulic davits - atop which sit our 530W solar array. The davits are a custom design of the previous owner built to lift a heavy RIB - which we would like very much to hang on them. While load-testing the lift capacity, I blew a seal on one of the lift cylinders thus beginning the task of repair or replacement. I decided to "replace" since the original cylinders were of the "welded" type (have to cut it open to service any seals) - deciding to go to a unit that was designed to be serviced with a cap-wrench. Cylinders arrived but the upper and lower cross-tubes had to be modified to fit the davit lift yokes...plus, the new cylinders have more lift capacity so the fluid couplers/fittings also have to be modified as well. The search continues for the right sized fittings and I hope to have parts on hand to accomplish reassembly within the week.

Musings on these projects had me chasing "squirrels" as I continually "cogitated" on improvements that would be wise investments:

- All that for 8 inches? To lift our RIB, the stroke on the cylinders had to be at least 8 inches. This would allow the davits to travel the appropriate distance (arc) to lift (and lower) our heavy 650 lb RIB. I considered hanging a 7-1 purchase block set from them to simply pull the RIB up to the arms but realized that the davit "arc" was designed to begin lifting the RIB (as it sat in the water) off of our swim platform finding that a "straight lift" from the full-up position on the davits would drag the RIB over the swim platform (hence the design had a purpose - to clear the platform as the lift commenced). Keeping the original design was going to be the right answer! The search for replacement cylinders was a long one (several weeks) - finally found a near-suitable fit from Prince Hydraulics (gotta love GOOGLE!) after discovering that repair would be equal or above the cost of replacement! Cylinder "stroke" and closed cylinder length to fit our rig was challenging - couldn't seem to find one (right stroke) with a "compatible" other (14" closed length)...but Prince had a "close-enough" option for which I was willing to make modifications. We are 2-weeks into the problem and the RIB is still not "lift-able!" The right fittings will do the trick...task #1 for this weeks lunch hour travels.

- A winch will still be nice? I still plan to put a winch on the davit-rig for a few reasons...first, to tighten up the RIB to the davit arms for stability instead of the harness just letting the RIB swing with motion. Still have to work out this math? Second...a winch would allow us to deploy a "kedge" anchor astern if we needed to pull ourselves off of a grounding. The winch (an ATV 2500 lb'er) will need to be modified (divide the winch drum into 2 x halves to pull from opposite directions) to accommodate the 2-point lifting bridle for the RIB. Either half can be used for kedging). The turning blocks will need to be sturdy enough to hold 650 lbs and we will use high-strength poly rope on the drum.

The Aft Holding Tank Project: The Admiral's nose is sensitive and she has prompted me to investigate the "musty" smell in the aft head (likely permeation of the old septic hoses). Since our new (to us) marina is an NDZ - we also needed to increase black-water tankage. Aforethought a few years ago prompted me to design (and have fabricated) an aft waste tank that would fit against the hull and give us around 20 gals of tankage to serve the aft head (which already has an MSD-1 at the ready). Living in an NDZ required me to "muse" upon the multi-functionality of the aft septic system. I wanted a 3-way capability: (1) Toilet to MSD-1 to overboard (when authorized); (2) Toilet to Overboard (when authorized); and (3) Toilet to tank to pump-out (legal all of the time). I decided to add a 4th capability... (4) Tank to overboard (with a second macerator pump) ... This permits us to fill the tank in an NDZ and dump it when we are far off-shore (such as visiting anchorages in protected environments like the Tortugas). During this project, we have also decided to replace the septic lines with the high-end non-permeable stuff to eliminate the penetration odors we often catch a whiff of during the summer season. We will do the forward head in mirror fashion adding tankage gages to both systems. The aft tankage is plumbed - I am ready to crack open the old septic lines for hose replacement and join the new tankage set-up to the existing system - but have been procrastinating...it's a "shitty" job but somebody has to do it (ME)!...so I've decided to do it while the Admiral is away on travel. PRAY for a clean (no spill) job PLEASE! The useful lesson learned is "don't scrimp" on septic hose. It is thick/stiff stuff! A heat gun is a must have for this project to soften it up and make tight, double-clamped connections!

Running Rigging Changes..."Yeah - but it's WIDE? Our jib, spinnaker and 3rd reef (main) lines were 5/8 inch double-braid. Although this "thick" line is pleasant to handle (over a thinner line), the gage of this rigging was heavy and would often "slow down" in the blocks or sheet-locks and "drag" on the gunnels in light winds (in the water). I replaced it with 5/16 inch double-braid and love it! The heavier stuff will be re-purposed to anchor rode for the stern anchor since each coil is 150 ft. Musings after replacing these lines are: Lighter is better (we will not likely stress tensile and stretch limits of the new lines) and lighter is faster (turning and locking cleat travel is now effortless).

Comments

| Vessel Name: | Take Me There! |

| Vessel Make/Model: | GULFSTAR M53 Ketch |

| Hailing Port: | Tampa, FL (Currently on the Chesapeake Bay) |

| About: | |

| Extra: |

SV Take Me There!

Port: Tampa, FL (Currently on the Chesapeake Bay)